Jctprint Machinery Co., Ltd

Questions about our anilox rollers

Product Name: Apex International Flexographic Printing Ceramic Anilox Roller

Origin: CHINA

Diameter range: 25-600 mm

Screen count range: 30-2000 LPI

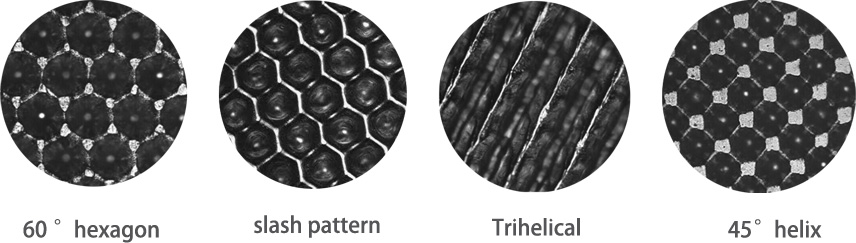

Cell shapes: hexagon, diamond, triple helix, etc.

cell angle: 60°, 45°, 30° and other special requirements

Maximum width: 5500 mm (shaft)

Which brand of printing press is used? Heidelberg, Komori, manroland, etc.

What kind of printing press is used? Flexographic and gravure printing machines of any brand

Minimum order quantity: 1 piece

Warranty period: 1 year

Delivery time: 20 working days for payment

Shipping method: DHL UPS TNT EMS Fedex or send to your freight forwarder

As a leading manufacturer of flexographic graphics laser engraved ceramic anilox papers, printing cylinders and other related products, our mission is to serve flexographic printing companies worldwide with good quality and best service.

Reasons why global customers recognize us

1. Base roller process:

All base rollers are produced by ourselves. For the base roller, usually we use #45 seamless steel pipe, the thickness is 15mm-25mm according to the size of the roller. We can also make special thickness according to customer requirements. But usually the above information is enough to make the finished product have a long life.

If the customer requires light enough weight, we can also use No5 series aluminum as the base roller.

We will check all dimensions according to customer confirmed drawings, surface roughness, straightness, dynamic balance, cylindricity, etc. If there are any small issues with this information, we will not use the roller in the next step, but make a new one to ensure quality.

2. Ceramic spraying

We use the famous plasma spraying machine, which comes from Oerlikon, Switzerland. The chromium oxide ceramic we use also comes from this supplier, and it can reach a hardness of 1200HV. The advantage of this supplier's ceramic powder is that the uniformity can be well controlled, 80% can be between 15u-35u, but 30% of other brands can only be between 15u-35u.

3. Anti-corrosion treatment

Ceramic anilox rolls corrode easily and reach solvents. Once the solvent reaches the base roller, it will be corroded by the bubbles, and then we can no longer use it. But because we use nano sealant to coat the ceramic surface. This sealant can reach tiny cells, thus enabling good corrosion-resistant production.

4. Precise delivery of ink

For each roller, we will do a trial engraving before the real engraving. After that, we will use the scanner to scan each layer to test the volume of cells, and then ensure the LPI we want to achieve based on the relationship between LPI and BCM.

5.Quality control

We have a quality control system throughout the entire production process, and our principle is to ensure that every roll is qualified.

6. Service life

Under normal operation and maintenance, our ceramic anilox rollers can work for 8-10 years or even longer.

Welcome to contact us:[email protected]