Choosing and Utilizing Doctoring Blades in Printing

When it comes to the selection and use of doctoring blades in the printing industry, various aspects need detailed consideration to ensure optimal performance and efficiency.

1. Material Selection:

- Rubber Blades: Typically used on softer printing surfaces such as paper or film. Known for their elasticity and adaptability, they gently scrape off ink, avoiding any potential damage to the printing rolls.

- Polyurethane Blades: These offer high durability and effective ink removal. They are suited for more rigid printing surfaces and ensure a longer lifespan and greater stability.

- Steel Blades: Ideal for surfaces with stringent requirements. While steel offers exceptional wear resistance and effectiveness, it needs to be handled with care to prevent damage to the printing rolls.

2. Blade Angle and Pressure:

- Angle: The angle of the blade significantly influences its scraping effectiveness. The right angle ensures efficient removal of residues and ink without exerting excessive pressure on the printing rolls.

- Pressure: Proper blade pressure guarantees even ink transfer. However, excessive pressure may lead to blade wear or damage to the roll surface. Therefore, balancing blade pressure is crucial for optimal printing results.

3. Adaptability and Customization:

- Printing Machine Characteristics: Choosing a blade that suits the requirements of specific printing equipment is vital. Different machine models might demand varying blade types or specifications.

- Printing Conditions: Considering the material type and surface characteristics is necessary. Different materials may require different types of blades to achieve the best printing results.

In the utilization phase, doctoring blades should effectively achieve the following:

- Effective Ink Control: Ensuring an even spread of ink or coating on the printing rolls for consistent and clear printing outcomes.

- Efficient Cleaning and Scraping: The blades should efficiently remove residues, keeping the printing process clean and preventing impurities from affecting the print quality.

- Reduced Friction and Wear: Properly chosen and used doctoring blades can minimize wear and friction on printing equipment, thereby extending the equipment's lifespan.

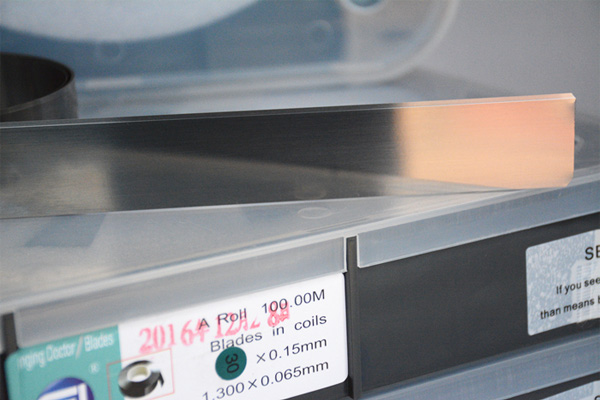

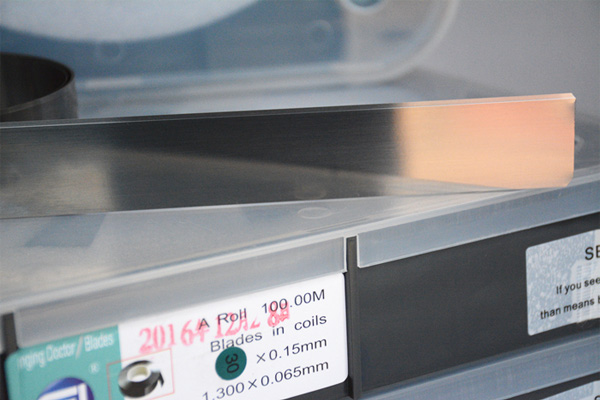

JCTPRINT doctoring blades

In summary, the correct choice and use of doctoring blades demand considerations regarding material selection, blade angle and pressure, adaptability, and customization. These factors aim to ensure that the blades effectively control ink and maintain cleanliness in the printing process while minimizing the impact on printing equipment.