Jctprint Machinery Co., Ltd

Our machine is easy to use , don't need to adjust the ink manually.The only thing you need to do is setting the viscosity value according to the product requirement and then the pulse detectorwill test the viscosity and the pneumatic diaphragm pump circulate ink and glue.

Automatic Glue Viscosity Controller For Coating Machine Ink Viscosity Regulator

1.Product Introduction

The viscosity controller is suitable for printing industry to automatically dilute the viscosity of the ink, and glue.

Our machine is easy to use , don't need to adjust the ink manually.The only thing you need to do is setting the viscosity value according to the product requirement and then the pulse detectorwill test the viscosity and the pneumatic diaphragm pump circulate ink and glue.

It's safe and reliable to operate, and the viscosity detection is accurate.The viscosity controller automatically tracks and monitors to make the viscosity consistent when printing, lamination and coating.

2.Specifications of our viscosity controller

| Model | V-10 | V-15 | V-20 |

| Appearance | 304 stainless steel,detachable box | 304 stainless steel,detachable box | 304 stainless steel,detachable box |

| Dimension | 300*320*750mm | 300*320*750mm | 300*320*750mm |

| Net weight | 17.5kg | 20kg | 23kg |

| Viscosity control range | 3#Zahn Cup 13-30sec/30-100cP | 3#Zahn Cup 13-30sec/30-100cP | 4#Zahn Cup 10-60sec/100-1000cP |

| Solvent tank | 304 stainless steel tank, capacity:12L | 304 stainless steel tank, capacity:12L | 304 stainless steel tank, capacity:12L |

| Inlet tube | 6.5mm*10mm*2.5m | 11mm*16mm*2.5m | 15mm*21mm*2.5m |

| Outlet tube | 8mm*12mm*2.5m | 11mm*16mm*2.5m | 15mm*21mm*2.5m |

| Ink circulating Rate | 1.5-4.5L/min | 3.5-9L/min | 7.5-19L/min |

| Air consumption | 40L/min | 90L/min | 160L/min |

| Working pressure | 0.3Mpa | 0.3Mpa | 0.3Mpa |

| Voltage/power | 220V/40W | 220V/40W | 220V/40W |

| Application range | Gravure printing,Flexo printing (Sub tank under 20L) | Gravure printing,Flexo printing,compound,coating (Sub tank under 40L) | Gravure printing,Flexo printing,compound,coating (Sub tank over 40L) |

3.Advantages?

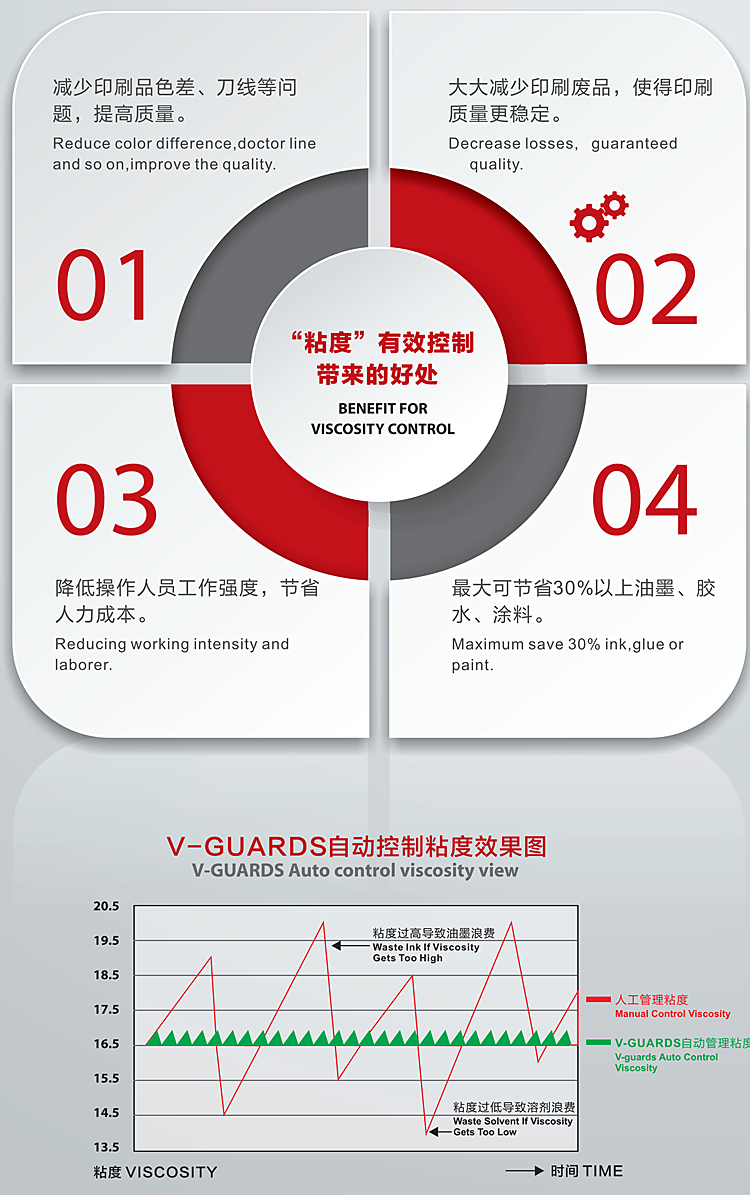

4.Why we need to use tension controller?

1). Reduce the color difference, knife line and other problems, improve the quality.

2). Greatly reduce the printing waste, making the printing quality more stable.

3). Reduce operating strength and labor cost.

4). Can save more than 30% of ink, glue, paint

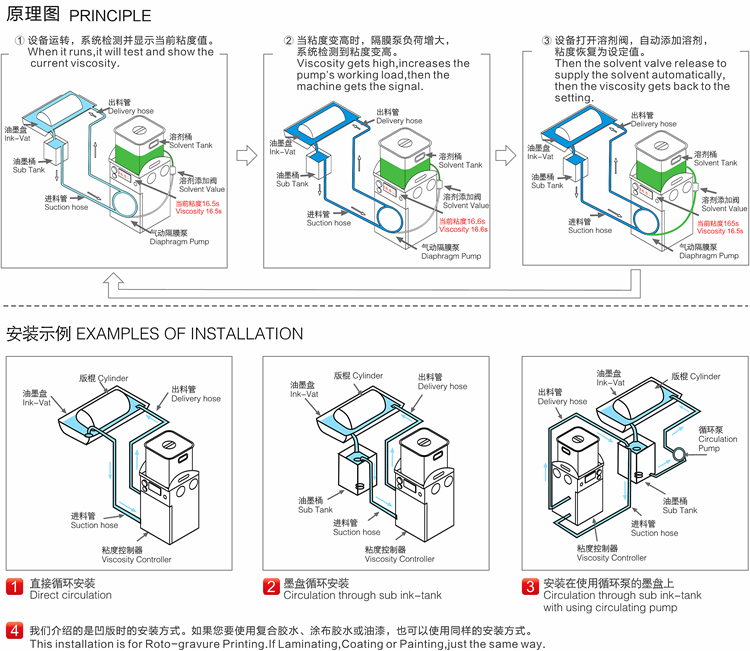

5.How to install the tension controller

Company Information

FAQ

1.Are you manufacturer or Trading company?

We are manufacturer and we have been producing viscosity controller for many years and our machine are sold to more than 20countries in the world and have good reputation.

2. Do you have quality certificate?

Yes ,we have CE, SGS etc,so you can rely on the quality.

3.What's the delivery time?

Around 20~30days after pre payment received, however, based on order.

4.Can you provide foreign country machine instation services?

Yes,we have a after service team can provide instation services and engineers are available to solve prolems overseas.

5.What’ s the terms of payment?

Usually T/T 100% in advance payment.We can also accept Western Union,paypal and credit card.