Jctprint Machinery Co., Ltd

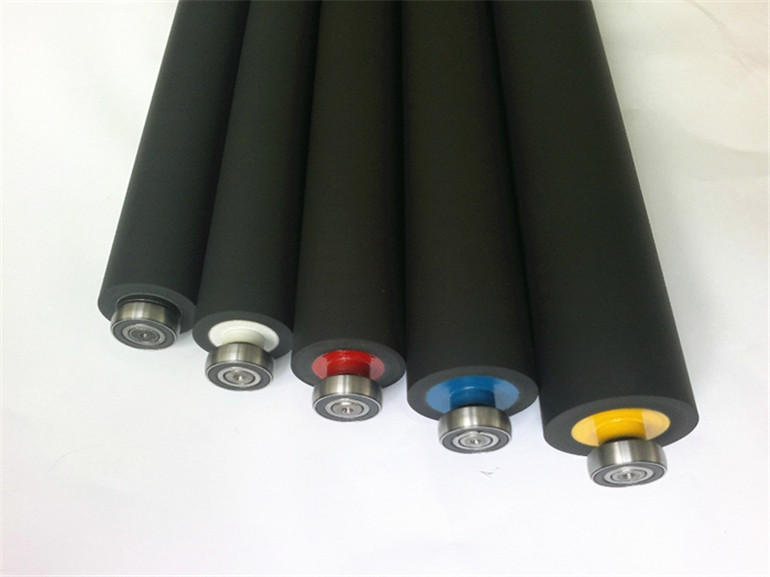

Offset printing rubber roller water ductor roller

Printing roller

Stretch roller

Back-up roller

Hot stamping pressure roller

Water roller

Traction roller

Ink roller

Gravure pressure roller

Alcohol water roller

1.What’s rubber roller

The rubber roller is generally composed of an outer layer rubber, a hard rubber layer, a metal core, a roll neck and a vent hole.

2.Appication

Rubber roller is mainly used in papermaking, printing and dyeing, printing, grain processing, metallurgy, plastic processing and so on.

3. Advantages of our rubber roller

A.Raw materials :

1) Base roller:

we are using is #45 steel or #20steel seamless pipe.And we are adopting a reasonable thickness base roller according to customer’s drawing. Some manufacturers will reduce the thickness of the steel pipe in order to get the price advantage.Such roller can’t meet the standards.But we won’t do that.

2)Rubber:

Our rubber are all imported from Germany or the US and then we mix them in our factory.The rubber coating technical we are using is winding technical. we casting the rubber on the base roller layer by layer and then vulcanize it to make the green rubber into mature rubber.

While other manufacturers are using sheet coating technical,and the rubber is cold in processing and will cause adhesion problems easily.

B. Production process:

1) Dynamic balancing:Before installing shaft head, we will do dynamic balancing test twice for each rubber roller,which will ensure the using effect.

2) Hot charging technicals:Adopt hot charging technicals to install the shaft head, and then weld after contraction to ensure the quality of shaft installation.While other supplier are welding the shaft head directly.

Workshop pictures