Jctprint Machinery Co., Ltd

Meta Description:

Is your friction shaft causing downtime? Discover 5 warning signs and why switching to multi-bladder air shafts from JCT Printing can boost productivity by 30%. Get a free technical consultation today!

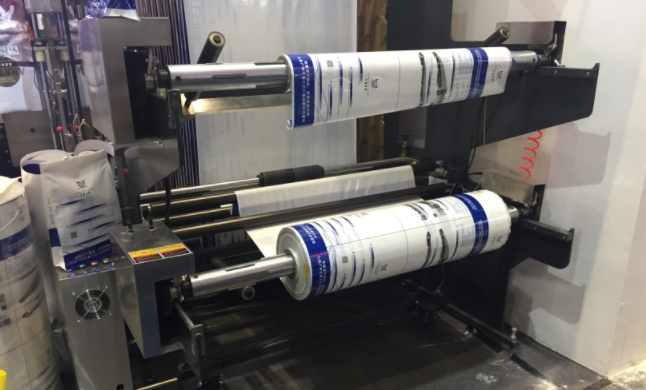

Friction shafts are workhorses in printing, packaging, and textile machinery, but wear and tear can lead to costly breakdowns. At JCTPRINT, we’ve helped over 200 manufacturers transition to high-performance air shafts with measurable ROI. Here’s how to diagnose failing friction shafts and explore superior alternatives.

Symptom: Wrinkled or misaligned substrates during unwinding/rewinding.

Root Cause: Worn friction liners or inconsistent pressure.

Air Shaft Advantage: Multi-bladder systems provide even radial force across the entire roll width.

Symptom: Rolls stall or surge during high-speed operation.

Root Cause: Loss of surface grip due to contamination (ink, dust).

Air Shaft Solution: Self-cleaning bladder designs maintain consistent traction.

Symptom: Operators constantly tightening bolts or replacing shims.

Root Cause: Mechanical wear in friction components.

Upgrade Benefit: Air shafts offer tool-free inflation/deflation for instant core gripping.

Symptom: Scored shafts, dented cores, or cracked end plugs.

Risk: Can damage expensive materials (e.g., film, foil).

JCT’s Fix: Our reinforced polyurethane bladders resist abrasion and chemicals.

Symptom: Motors overheating due to excess friction.

Data Point: Air shafts reduce drag by up to 40% (case study available).

Compared to friction shafts, JCT’s air shafts deliver:

✅ 30% Faster Changeovers (No mechanical parts to adjust)

✅ Adaptability – Fit any core size from 3" to 20" with one shaft

✅ Longer Lifespan – Minimal wear parts vs. friction pads

See Our Air Shaft Product Line →

Load Capacity: Match to your roll weight (e.g., 500kg vs. 2-ton rolls).

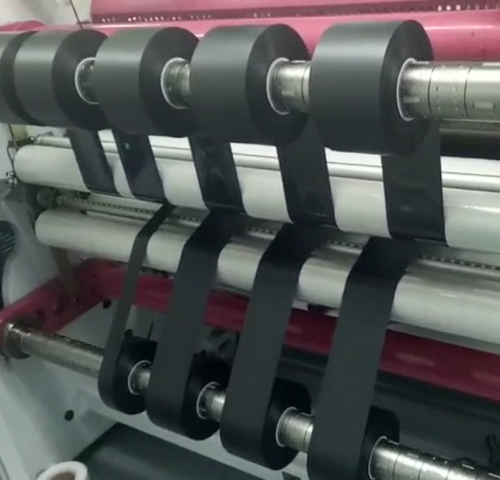

Bladder Configuration: Multi-bladder for wide webs (>1m), single for narrow.

Speed Rating: Our HS-series supports 600m/min+ for high-speed presses.

Pro Tip: Request a free on-site assessment to calculate your ROI.

Q: Can I retrofit air shafts to old machines?

A: Yes! 85% of our installations are retrofits – we provide custom adapter kits.

Q: How long do air shaft bladders last?

A: Typically 3-5 years with proper maintenance (we offer replaceable kits).

Don’t let friction shaft failures disrupt your production. JCTPRINT specializes in drop-in air shaft upgrades for printing and packaging lines.