Jctprint Machinery Co., Ltd

Anilox rollers are critical to maintaining ink consistency, print quality, and operational efficiency in flexographic printing and coating applications. But even the best ceramic anilox rollers can fail prematurely if they are not properly handled, cleaned, or specified.

In this article, we’ll explore the top 7 reasons why anilox rollers fail—and more importantly, how you can prevent these failures to maximize performance and roller life.

Problem: Dried ink and coating materials clog the engraved cells, reducing ink volume transfer and leading to poor print quality.

Prevention:

Implement a regular cleaning schedule with approved chemicals and ultrasonic or laser cleaning.

Avoid aggressive tools that scratch the ceramic surface.

Use automatic cleaning systems when possible.

Tip: JCTPRINT provides professional cleaning advice and support for all types of ceramic anilox rollers.Ultrasonic anilox roller cleaning machine

Problem: Storing anilox rollers vertically, in humid or dusty environments, can damage the engraving or cause corrosion at shaft ends.

Prevention:

Always store rollers horizontally in dry, clean, and vibration-free locations.

Use protective covers for anilox sleeves and rollers when not in use.

Problem: Accidental drops or contact with metal tools can cause micro-chips in the ceramic coating.

Prevention:

Train operators on safe handling procedures.

Use roller-specific carts or cradles.

Avoid using screwdrivers or sharp objects to pry rollers out of position.

Problem: Incorrect blade pressure or poor alignment accelerates wear on the ceramic surface and can even damage the cell structure.

Prevention:

Calibrate blade pressure to OEM specifications.

Regularly check blade condition and replace when worn.

Use appropriate blade materials for your ink/coating system.

Problem: Mismatch between the anilox roller’s engraving and your ink, substrate, or print type can result in over-inking, mottling, or detail loss.

Prevention:

Consult with your anilox roller manufacturer to select the right line screen and volume for each job.

Consider dual-roller setups for flexible production needs.

JCTPRINT offers custom-engraved anilox rollers based on your exact print requirements, from 100 to 1500 LPI.

Problem: Harsh chemicals can degrade the ceramic coating or corrode the roller core, especially in cheaper constructions.

Prevention:

Use manufacturer-recommended cleaning agents.

Avoid prolonged soaking in aggressive solvents.

Choose high-quality ceramic anilox rollers with corrosion-resistant cores.

Problem: Over time, wear and tear reduce cell depth and ink volume capacity—even with high-quality ceramic rollers.

Prevention:

Periodically measure cell volume using microscopes or ink proofer tools.

Replace rollers before quality loss becomes critical.

Partner with a reliable supplier offering roller diagnostics.

| Cause of Failure | Solution Summary |

|---|---|

| Clogged cells | Regular, gentle cleaning |

| Poor storage | Horizontal, dry, covered storage |

| Handling damage | Use safe tools and training |

| Blade misalignment | Correct pressure and quality blades |

| Wrong LPI/BCM | Match roller specs to ink/substrate |

| Chemical damage | Use safe, approved solvents |

| Normal wear | Periodic inspection and timely replacement |

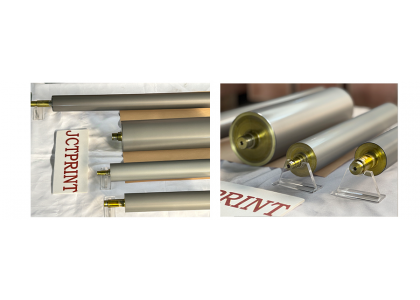

With over 20 years of experience, JCTPRINT manufactures durable, high-performance ceramic anilox rollers, anilox sleeves, and full flexo printing solutions trusted in over 40 countries. We not only deliver precision-engineered products, but also provide ongoing support in cleaning, maintenance, and specification selection.

✅ Wide range of anilox line counts & volumes

✅ Custom solutions for flexo printing anilox and coating anilox applications

✅ Fast delivery and responsive technical support

Contact us today to optimize your anilox roller performance and extend equipment life.