Jctprint Machinery Co., Ltd

In flexographic printing, selecting the right plate mounting sleeve is crucial for enhancing production efficiency, print quality, and reducing operational costs. By understanding the specific requirements of the customer’s machinery, products, and factory scale, you can help them choose the most suitable sleeve. Below is a complete guide that addresses the four key questions to assist customers in making informed decisions.

Plate mounting sleeves are particularly effective on machines that require both high efficiency and precision. The two main types of flexo presses where sleeves excel are:

Central Impression (CI) Flexo Press: This type of large flexo press frequently requires fast plate changes due to its multi-color printing capabilities. Plate mounting sleeves significantly enhance production efficiency while maintaining high registration accuracy, reducing downtime.

Modular Flexo Press: For small to medium-sized enterprises, modular flexo presses offer flexibility to meet various production demands. Using plate mounting sleeves on such machines allows for quick plate changes, improving line adaptability and responsiveness to market fluctuations.

Plate mounting sleeves are widely used in flexo printing, particularly for the following products:

Packaging Printing: Ideal for high-volume production in industries like food packaging, pharmaceutical packaging, and fast-moving consumer goods. These products require both high print quality and efficiency. The quick-change capabilities of plate mounting sleeves can significantly speed up production while maintaining precise registration.

Label Printing: High-precision label printing demands accurate registration. Plate mounting sleeves ensure consistent, high-resolution prints, reducing waste and improving product uniformity.

Film Printing: For customers printing on flexible materials like plastic films, plate mounting sleeves provide stability during long runs at high speeds, preventing registration errors caused by material stretching.

The scale of a factory’s production plays a key role in determining whether plate mounting sleeves are the right choice. Here are recommendations based on different production scales:

Large-Scale Production Facilities: For factories running multiple production lines and operating 24/7, plate mounting sleeves are essential for increasing efficiency. Their quick-change capability significantly reduces downtime, ensuring continuous and stable production at high output levels.

Medium-Sized, Flexible Production Enterprises: If the factory frequently switches between products and production tasks, the flexibility and ease of operation provided by plate mounting sleeves can help respond to varying demands. This improves line adaptability and speeds up task changes.

Choosing the right plate mounting sleeve brings numerous benefits to the customer’s production, including optimized workflows, enhanced product quality, and reduced operational costs. Key advantages include:

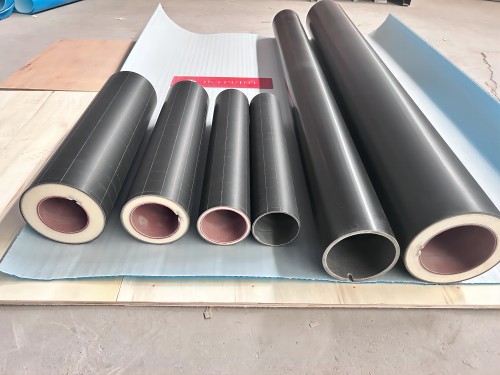

Increased Production Efficiency: The lightweight design and easy installation of plate mounting sleeves allow for rapid plate changes, particularly in environments where frequent job changes are required. This reduces downtime and improves overall production speed.

Improved Print Quality: The smooth and rigid surface of plate mounting sleeves ensures precise plate positioning throughout the print process, reducing waste caused by vibration or registration errors, and guaranteeing consistent print quality.

Reduced Operational Complexity: Traditional plate changes are time-consuming and labor-intensive. Plate mounting sleeves, being lightweight and easy to handle, reduce the need for heavy equipment and manual labor, making them ideal for companies looking to streamline operations.

Lower Maintenance Costs: High-quality plate mounting sleeves are designed for durability, with longer lifespans and minimal maintenance needs. This helps reduce equipment downtime and repair costs, leading to long-term savings.

Enhanced Production Flexibility: For customers frequently switching between different product batches, plate mounting sleeves offer quick adaptability, enabling fast transitions between print jobs and increasing production flexibility to meet market demands.

When selecting plate mounting sleeves, it is essential to consider the customer’s specific flexo press type, the products they are printing, and the scale of their factory. Plate mounting sleeves are particularly beneficial in environments where quick plate changes and high print precision are required. They greatly improve production efficiency, reduce maintenance costs, and ensure consistent print quality.

Whether the customer is involved in large-scale packaging production or high-precision label and film printing, plate mounting sleeves can provide substantial advantages. These sleeves not only optimize production workflows but also enhance a factory's competitiveness in a fast-changing market, supporting sustainable production growth.