How to Choose the Right Air Shaft for Winding and Unwinding Plastic Film — Customer Selection Guide

How to Choose the Right Air Shaft for Winding and Unwinding Plastic Film — Customer Selection Guide

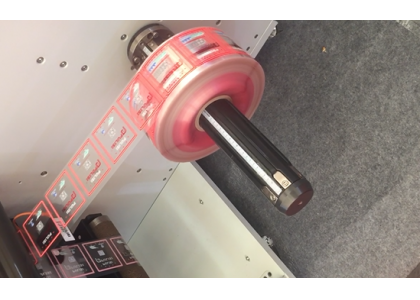

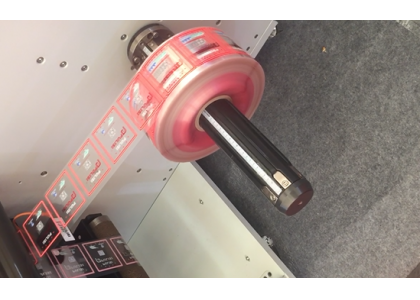

In industries such as printing and packaging, winding and unwinding plastic film is a critical part of the production process, and air shafts play a key role in this operation. Choosing the right air shaft not only improves production efficiency but also ensures the quality of the plastic film roll, reduces waste, and minimizes operational costs. This guide will help you understand how to choose the right air shaft based on your specific needs, enabling you to make an informed decision.

1. Characteristics of Plastic Film Rolls

Before selecting an air shaft, it is essential to understand the characteristics of the plastic film you are working with. Different types of plastic films have varying requirements, so consider the following factors:

-

Roll Weight: Plastic film rolls are generally light, but in mass production, the total weight can increase significantly with the length of the film. Make sure the air shaft can support the maximum roll weight.

-

Roll Width: Plastic film comes in various widths, from a few hundred millimeters to several thousand millimeters. The length of the air shaft must match the width of the roll to ensure even tension distribution across the entire width.

-

Film Fragility and Flexibility: Plastic film is relatively thin and can be easily damaged. To avoid scratches or pressure marks, it is important to choose an air shaft that provides even expansion force and gentle handling of the film.

2. Types of Air Shafts Suitable for Plastic Film

Different types of air shafts are suitable for various applications and film types. Here are the common types of air shafts and their ideal applications:

1. Leaf Type Air Shaft

- How It Works: This air shaft uses an air bladder to expand multiple leaves that evenly grip the inner surface of the roll core. The even distribution of pressure makes it suitable for handling delicate materials.

- Advantages: The expansion force is even, reducing the risk of pressure marks or damage to the plastic film. Ideal for handling lightweight film rolls.

- Best For: Lightweight to medium-weight plastic film rolls, especially in applications requiring delicate handling.

2. Lug Type Air Shaft

- How It Works: This type of air shaft has metal lugs that expand and firmly grip the core when inflated, providing strong support.

- Advantages: High load-bearing capacity, making it suitable for heavier plastic film rolls.

- Best For: Large-diameter cores and heavy rolls, especially in large-scale production. Its strong grip is ideal for high-speed lines, but be cautious with thin-walled cores to avoid deformation.

3. Differential Air Shaft

- How It Works: This air shaft uses multiple independently controlled air bladders, allowing for handling multiple rolls of different widths while adjusting tension for each roll.

- Advantages: Provides precise tension control and is ideal for simultaneous processing of multiple rolls.

- Best For: Applications where multiple rolls are processed at once or where precise tension control is required between different rolls.

3. How to Choose the Right Air Shaft

When selecting an air shaft, the following considerations are key based on your specific plastic film characteristics and production process requirements:

1. Roll Size and Weight

- Core Diameter: The inner core diameter of plastic film rolls is usually 3 inches (76 mm) or 6 inches (152 mm). The air shaft must match the core diameter to ensure a secure grip after inflation.

- Roll Weight: For heavier rolls, choose a lug-type air shaft with high load-bearing capacity. For lighter rolls, a leaf-type air shaft can provide sufficient support.

2. Expansion Method

- Even Expansion: For thinner and more delicate films, a leaf-type air shaft is ideal due to its even expansion, which helps prevent pressure marks.

- Quick Lock and Release: For high-speed production lines, fast inflation and deflation are critical. Lug-type air shafts, with their powerful expansion force, can quickly grip and release the core, improving roll change efficiency.

3. Tension Control

- Tension control is vital when handling plastic films. If precise tension control is needed, particularly when processing multiple rolls simultaneously, a differential air shaft is the best option. It ensures uniform tension across different rolls, preventing creasing or damage.

4. Ease of Use and Maintenance

- Ease of Operation: Select an air shaft that is easy to operate, especially in scenarios with frequent roll changes. Fast and easy operation reduces downtime.

- Maintenance and Durability: Consider the maintenance requirements of the air shaft. Opt for a product with a long maintenance cycle and low failure rate. Leaf-type air shafts are generally easier to maintain, while lug-type air shafts may require more frequent upkeep.

5. Customization Needs

- Depending on the specific needs of your production line and rolls, a customized air shaft might be the best option. Customization can include length, diameter, expansion method, and load-bearing capacity to match your exact requirements.

4. Recommended Air Shaft Brands

There are several reputable brands that provide high-quality air shafts. Here are some companies that excel in plastic film roll handling:

-

Tidland

- A global leader in web handling equipment, Tidland offers a wide range of air shafts suitable for different roll weights and widths. Their lug-type and leaf-type air shafts perform excellently in plastic film handling with durability and efficiency.

-

Goldenrod Corporation

- Known for their lightweight air shaft designs, Goldenrod’s products are ideal for handling lightweight plastic film. They are easy to operate and provide strong load-bearing capabilities for medium and heavy rolls.

-

JCTPRINT

- Advantages: JCTPRINT manufactures air shafts with high precision, offering affordable pricing and long lifespan. Their products are custom-made according to the client’s production line specifications, ensuring a perfect match with the equipment and improved operational efficiency. JCTPRINT is an excellent choice for customers looking for cost-effective yet high-quality solutions.

-

Re Spa

- This brand offers highly customizable web handling solutions, making them ideal for production lines that require tailored air shafts. Their products offer precise tension control and fast roll change solutions.

-

Double E Company

- Specializing in high-performance, durable air shafts for industrial applications, Double E’s products are ideal for high-speed lines and heavy-duty roll handling

5. Conclusion

Choosing the right air shaft is crucial for the winding and unwinding of plastic films. By selecting an air shaft that matches the roll’s weight, width, and production requirements, you can significantly improve efficiency and protect the film from damage. Leaf-type air shafts are ideal for lightweight rolls, while lug-type air shafts are better suited for heavier rolls. In applications that require precise tension control, differential air shafts are the best choice. Additionally, factors like ease of use, maintenance costs, and the need for customization should be taken into account when making your decision.

By following the advice in this guide, you will be well-equipped to select the most suitable air shaft for your production needs, achieving higher efficiency and better product quality.