Jctprint Machinery Co., Ltd

In the field of film printing, the anilox roller plays a critical role in controlling ink transfer and volume, directly affecting print quality, production efficiency, and cost management. Film materials, with their unique surface properties and low absorbency, require precise ink transfer. Therefore, selecting the right anilox roller is essential to improving performance in film printing. This article will explore key factors for choosing an anilox roller for film printing, backed by real-world data and case studies to help customers optimize their choice for everyday production.

Cell line count (LPI, Lines Per Inch) and volume (BCM, Billion Cubic Microns) are the core parameters that determine how much ink an anilox roller transfers. For film materials, which have low ink absorption, a higher line count with moderate cell volume is typically needed to ensure consistent ink transfer.

A film printing company using an 800 LPI high-line-count anilox roller successfully reduced ink consumption by 12% while also improving print clarity. High-line-count anilox rollers provide more precise ink transfer, ensuring color consistency and reducing waste. Compared to using a 500 LPI anilox roller, the company’s scrap rate decreased by 8%-10%, especially when printing intricate designs on transparent film packaging.

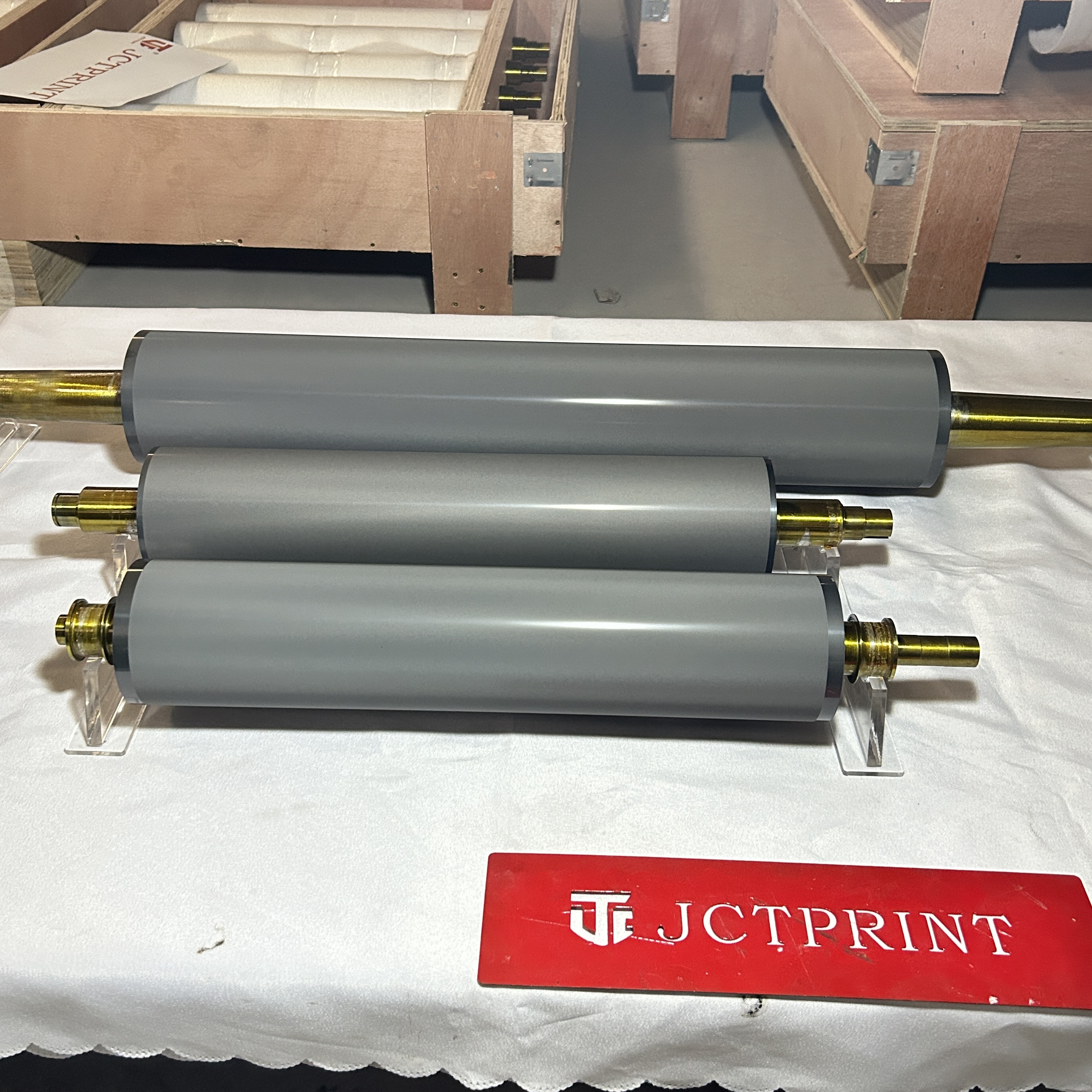

In high-frequency production environments, the durability of the anilox roller is crucial. While traditional chrome-plated anilox rollers are more affordable, their lifespan is limited, and they wear out quickly. Ceramic-coated anilox rollers, on the other hand, are more cost-effective for film printing due to their higher wear resistance and corrosion resistance.

A packaging company switched from chrome-plated anilox rollers to ceramic-coated ones, extending the roller's lifespan from 6 months to over 2 years. This change reduced maintenance and replacement costs by 25%. Additionally, the ceramic anilox roller’s cells remained intact for a longer period, reducing downtime by 15% and significantly boosting production efficiency.

The type of ink (e.g., solvent-based, UV, or water-based) directly impacts the choice of anilox roller. Solvent-based inks, commonly used in film printing for their fast drying time and high adhesion, require an anilox roller that ensures stable ink transfer to avoid color variation or ink build-up issues.

A high-end food packaging company faced challenges with inconsistent color during film printing. By adjusting the cell volume from 5 BCM to 3 BCM, the ink transfer became more precise, achieving 99% color consistency. This adjustment led to a 40% reduction in customer complaints and an 18% decrease in returns, greatly improving customer satisfaction.

In a high-speed production environment, the anilox roller must continuously transfer ink with stability. A high-quality anilox roller not only ensures consistent performance during long production runs but also minimizes downtime, thereby increasing the overall efficiency of the production line.

A film printing plant using ceramic-coated, laser-engraved anilox rollers increased print speed by 20% while maintaining excellent print quality. Thanks to the precisely engraved cells, ink was transferred uniformly, resulting in a 10%-15% reduction in ink waste. Moreover, ink stability was maintained during extended runs.

Selecting an anilox roller that is easy to maintain and clean can greatly reduce machine downtime and improve overall production efficiency. Traditional anilox rollers can experience ink buildup or clogged cells, leading to more frequent cleanings and disrupting the production flow.

A printing company switched to new ceramic-coated anilox rollers, reducing cleaning frequency from twice a week to once a month. This lowered cleaning costs by 30% and significantly reduced downtime. The change led to a 15% increase in production efficiency, meeting the high-capacity demands of the company’s operations.

Film printing requires precise ink transfer, and the choice of anilox roller has a direct impact on production efficiency, cost, and quality. For customers with extensive experience in film printing, paying attention to cell line count and volume, durability, ink compatibility, print consistency, and maintenance costs is crucial. In practice, selecting a high-line-count, high-precision, and easy-to-maintain ceramic anilox roller can significantly enhance production efficiency and maintain high-quality results in large-volume and high-precision printing.

By incorporating specific data and case studies, customers can better understand how their choice of anilox roller influences production outcomes, allowing them to optimize their film printing processes and enhance competitiveness.