Jctprint Machinery Co., Ltd

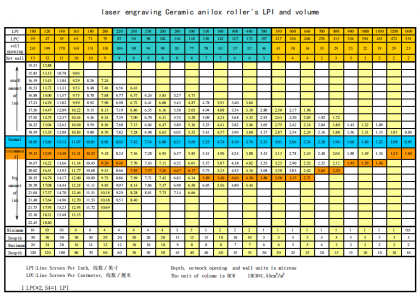

Anilox rollers are essential for ink or coating transfer in flexographic printing. The line count, or LPI (lines per inch), determines how much ink is transferred. Choosing the wrong line count can cause over-inking, lack of detail, or even production waste.

Line count refers to the number of engraved cells per inch on the roller surface. Higher LPI means finer cells and lower ink volume, ideal for detailed graphics. Lower LPI means larger cells, more ink transfer, and is suitable for bold, solid areas.

Are you printing flexible packaging, corrugated boxes, or applying coatings? Each needs a different LPI.

| Application | Recommended LPI | Cell Volume (BCM) |

|---|---|---|

| Coating / Varnish | 250–400 | 8–10 |

| General Flexo | 400–800 | 3–6 |

| High-Resolution Labels | 900–1200 | 1.5–2.5 |

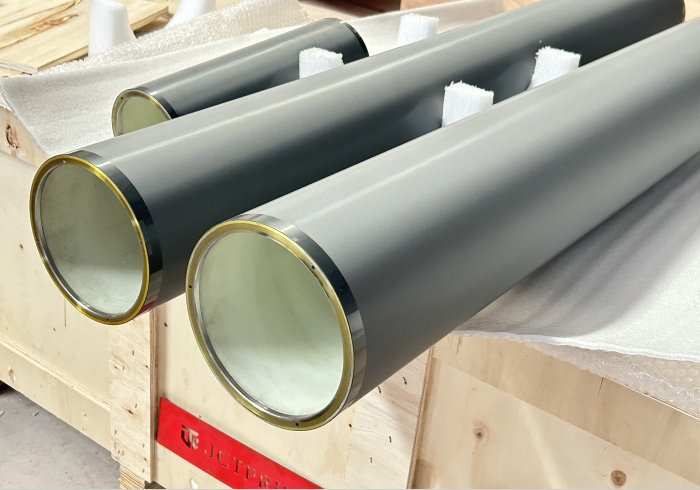

JCTPRINT offers custom ceramic anilox rollers, sleeves, and coating rollers tailored to your needs.

Use ultrasonic cleaning and volume measurement tools to maintain cell volume and prevent buildup.

With over 20 years of experience and clients in 40+ countries, JCTPRINT provides reliable solutions for flexo and coating industries. From anilox rollers to sleeves and rubber rollers, we offer precision and quality.

Contact us now for expert recommendations »

Engineered for varnish, glue, and functional coating applications.

View Details