Jctprint Machinery Co., Ltd

In the world of material winding and unwinding, air shafts play a crucial role in ensuring efficiency, precision, and safety. When choosing a pneumatic air shaft, one of the most important decisions is whether to go for a multi bladder air shaft or a single bladder air shaft. Each has its own advantages depending on the application, material, and machine type.

In this article, we’ll compare both options and help you decide which air shaft suits your equipment best.

Contact JCTPRINT to get a quote

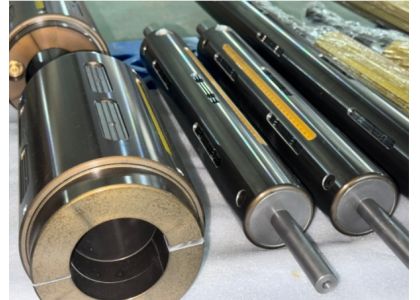

An air shaft (also known as a pneumatic expanding shaft or shaft air) is a mechanical device used to hold, expand, and lock cores during winding and unwinding processes. It works by inflating an internal bladder with compressed air, causing the shaft’s outer surface to expand and grip the core tightly.

A single bladder air shaft features one central bladder running through the shaft. When air is pumped in, the bladder expands and pushes outward, activating the lugs or expanding leaves to hold the core.

Cost-effective: Simple structure, lower manufacturing and maintenance cost.

Lightweight: Fewer internal components make it easier to handle.

Suitable for smaller loads: Ideal for narrow web applications or light roll weights.

Less uniform expansion: Centralized inflation may cause uneven pressure distribution on wide cores.

Limited holding force: Not suitable for high-tension or heavy-duty applications.

A multi bladder air shaft contains multiple separate bladders aligned along the shaft body. Each bladder can inflate simultaneously to provide balanced pressure along the entire shaft length.

Even expansion: Ideal for wide web materials, preventing core slippage.

Stronger grip: Suitable for high-speed machines and heavy roll materials.

Higher performance: Offers better stability, especially in high-precision operations.

Higher cost: More complex internal design.

Heavier weight: Additional components may add to the overall shaft weight.

Maintenance: More parts can mean slightly more effort in replacing bladders.

| Feature | Single Bladder Air Shaft | Multi Bladder Air Shaft |

|---|---|---|

| Core Size | Small to medium | Medium to large |

| Web Width | Narrow | Wide |

| Roll Weight | Light | Heavy |

| Speed | Low to medium | Medium to high |

| Precision Requirement | Basic | High |

| Cost | Lower | Higher |

Printing: Multi bladder shafts are preferred for wide-web flexo printing machines where roll slippage must be avoided.

Labeling: Single bladder shafts are common in narrow-web label printing applications.

Packaging: Depending on the roll width, both types are used in coating, lamination, and slitting equipment.

Textile & Paper: Multi bladder air shafts offer better performance for heavier and larger rolls.

Choosing between a multi bladder air shaft and a single bladder air shaft depends on your specific application needs. For high-speed, wide-web, or heavy roll applications, a multi bladder shaft provides superior grip and performance. For simpler, lighter tasks, a single bladder shaft offers a cost-effective and efficient solution.

Looking for a high-quality air shaft for your equipment? At JCTPRINT, we offer custom solutions for both pneumatic air shafts and expanding air shafts, built with durability and precision in mind. Contact us today to get a quote or technical support!