Jctprint Machinery Co., Ltd

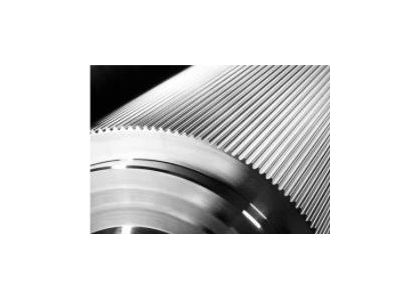

Corrugating rolls are the heart of every corrugated board production line. They are responsible for forming the flutes—the wavy layer that gives corrugated cardboard its strength, rigidity, and cushioning performance.

Understanding how corrugating rolls work, their structure, and material options can help packaging manufacturers achieve better quality, efficiency, and durability in production.

In this article, we’ll break down everything you need to know about corrugating rolls—from design and operation to the best materials for your production needs.

A corrugating roll (also known as a corrugating roller or flute roll) is a precision-engineered steel cylinder used in the single facer section of a corrugator.

Its main function is to press and shape the paper medium into flutes under heat and pressure. These flutes are then glued to linerboards to form corrugated cardboard.

A well-designed corrugating roll ensures:

Stable flute formation

Uniform flute height and pitch

High bonding strength between paper layers

Smooth and efficient production without paper breaks

A corrugating roll set typically includes:

Upper corrugating roll

Lower corrugating roll

Pressure roll (optional, depending on machine type)

Each roll is carefully machined to create precise flute shapes and maintain consistent temperature distribution.

Base Body (Core Shaft):

Made from alloy steel, providing strength and rigidity.

Flute Profile Surface:

Engraved with precise flute geometry (A, B, C, E, F types).

Coating Layer:

A protective surface (chrome, tungsten carbide, or ceramic) for wear resistance.

Steam or Heating Channels:

Maintain stable surface temperature for optimal paper forming.

This combination allows the roll to produce clean, consistent flutes even under high-speed and high-temperature conditions.

During operation, the corrugating medium (paper) passes between the upper and lower corrugating rolls, which rotate in opposite directions.

Under heat and pressure:

The paper softens and conforms to the flute shape.

Adhesive is applied to the flute tips.

The fluted paper is bonded to the liner to form single-faced board.

Precision, temperature control, and surface quality of the rolls directly affect:

Flute sharpness and accuracy

Bonding quality

Energy efficiency

Production speed

Different flute profiles serve different packaging needs.

| Flute Type | Flute Height (mm) | Common Application |

|---|---|---|

| A Flute | 4.8 – 5.0 | Strong cushioning for heavy-duty boxes |

| B Flute | 2.5 – 3.0 | Fine printing and retail packaging |

| C Flute | 3.5 – 4.0 | General shipping boxes |

| E Flute | 1.0 – 1.8 | Lightweight retail and display packaging |

| F Flute | 0.6 – 0.8 | High-end fine printing packaging |

Choosing the correct flute type ensures optimal strength, thickness, and surface finish for your product.

The choice of material and surface coating determines the roll’s lifespan, flute precision, and resistance to wear.

Alloy Steel: Standard material with good mechanical strength.

Forged Steel: High precision and excellent fatigue resistance for heavy-duty use.

Hard Chrome Plating:

Cost-effective and corrosion-resistant.

Suitable for medium-speed production lines.

Tungsten Carbide Coating:

Exceptional hardness and wear resistance.

Long service life (2–3 times longer than chrome).

Ideal for high-speed corrugators.

Ceramic Coating:

Superior surface stability and heat resistance.

Provides consistent flute quality under extreme conditions.

Selecting the right coating helps balance cost and performance based on your production volume and operating environment.

To maximize roll life and maintain product quality:

Clean regularly to remove glue and paper dust.

Avoid mechanical impact during installation and operation.

Check wear depth and flute precision periodically.

Use professional regrinding services to restore flute geometry.

With proper maintenance, a high-quality corrugating roll can last up to 40–60 million running meters before refurbishment.

As a professional roller manufacturer with over 20 years of experience, JCTPRINT provides:

Advanced tungsten carbide and ceramic-coated corrugating rolls

Customized flute designs for different corrugator brands

Precision machining with strict tolerance control

Complete after-sales support and regrinding services

Our corrugating rolls are used by packaging manufacturers in more than 40 countries, ensuring stable performance and long service life.

Corrugating rolls may look simple, but their design and material quality define the overall performance of your corrugated board production.

By understanding their structure, function, and material options, you can make informed decisions that lead to higher quality, efficiency, and cost savings.

If you’re looking for durable and high-precision corrugating rolls, contact JCTPRINT today — your reliable partner in corrugated production solutions.