Jctprint Machinery Co., Ltd

Product overview

1. Usage of ceramic anilox roller

1).Flexo printing machine(unit type ,central cylinder type,cascade type for Label , Envelope , Paper Forms , Handbag, Corrugated Box, Plastic Film printing)

2).Corrugated water-based ink printing slotting machine

3).Coating and lamination machine

4).Glazing machine ect.

2. Specifications of our ceramic anilox roller

Screen count range(LPI): 80-2000 LPI

Surface hardness: 1250HV-1350HV

Engraving angle( Screen angle): 1-89 degree

Cell shape : 30°honeycomb, 60°honeycomb(hexagon), 45°diamond(quadrangle,ART pattern ),curved flow(Cobra pattern), slanted(line pattern)or according to your actual requirement.

3.Why choose us?

1) Material advantage

Base roller: 45# seamless steel or No5 series aluminum

We adopt 45# seamless steel tube and the thickness is from 15mm-25mm based on the dimension of the roller.

And we can also use No5 series aluminum as the base roller if the customer wants lighter weight.

Surface coating: Chrome oxide ceramic

We use the famous plasma spraying machine from Switzerland supplier to do the coating spray. The evenness of 80% ceramic powder can be controlled between 15u-35u .

The hardness of chrome oxide ceramics can reach 1200HV-1350HV.

2) Technical advantage

Antiseptic treatment

we use the nanoscopic sealant to coat on the surface of the ceramic which can reach the tiny cell to protect the base roller from solvent corrosion.

Trial engraving to assure the precise delivery on the ink

First, We make trial engraving before the real engraving.

Second, we use the scanner to scan each layer to test the volume of the cell

Third, according to the realationship between the LPI and BCM , we can make sure whether the LPI is ok.

3) Quality advantage

Quality control system

We have the quality control system during the whole production from the very beginning to the end to make sure each roller is qualified.

For the base roller, we will check their surface roughness,straightness, dynamic balance,cylindricity and so on,we will do such incoming inspection on every rollers.

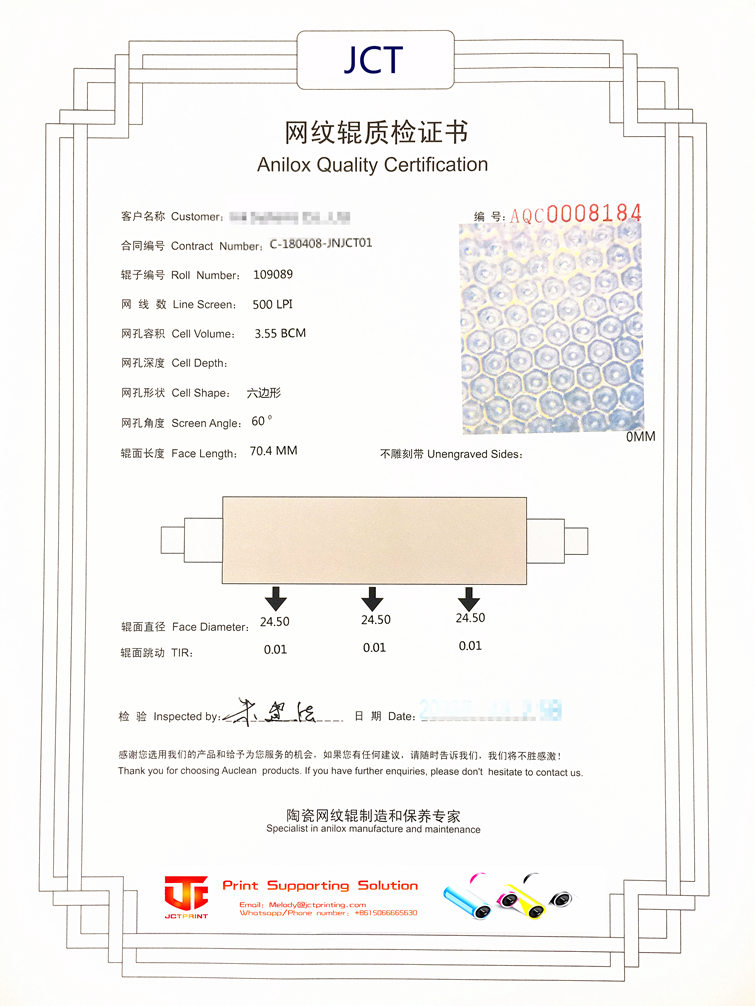

An anilox quality certification will be issued to our customer after each ceramic anilox roller is finished.

Long Service life:8-10years

Under nomal operation and maintenance,our ceramic anilox rollers can work 8-10years or even longer.

5. Packaging

We have two types of packaging wooden box and strong carton.

Company Information

FAQ:

1.How can I get a quotation?

Please advise the following information to our email address or add me on whatsapp,wechat and so on.

A.The drawing of the ceramic anilox roller if possible(or you can get a estimate price by telling us the total length,effective face length,diameter as the following picture.

B.LPI an BCM

C.Where do you use the ceramic anilox roller

2. I don’t know the BCM of the anilox roller,what should I do?

If you don’t have special request on BCM ,we will recommend you the standard type.

3.What's the delivery time?

Around35days after pre payment received,and it also depends on the quantity you want.

4.What’ s the terms of payment?

Usually T/T 100% in advance payment.We can also accept Western Union,paypal and credit card.