Jctprint Machinery Co., Ltd

Application:Flexo printing machine(unit type ,central cylinder type,cascade type);Offset printing machine;Corrugated water-based ink printing slotting machine;Coating and lamination machine;Glazing machine ect.

Ceramic cated anilox roller for flexographic printing machine

A. Flexo printing machine(unit type ,central cylinder type,cascade type)

B. Offset printing machine

C. Corrugated water-based ink printing slotting machine

D. Coating and lamination machine

E. Glazing machine ect.

Advantages:

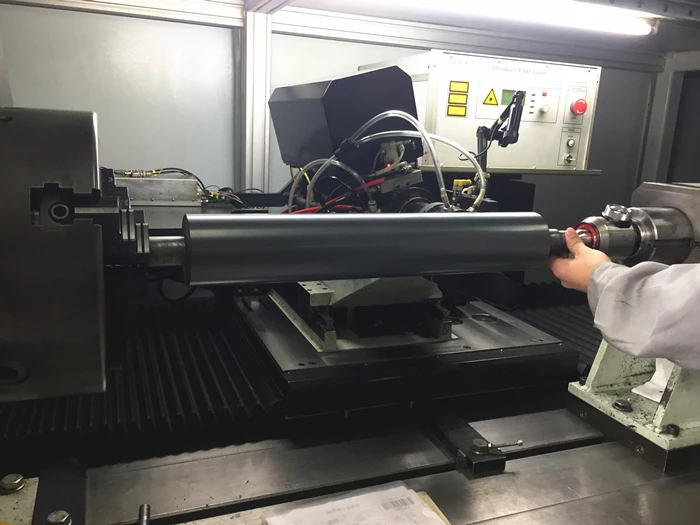

1. Base roller

A. Material:

45# steel tube or No.5 series aluminum;General performance requirement ;Lighter weight requirement : No5 series aluminum

B.Thickness : 15mm-25mm ;We can also make the special thickness according to customers requirement.

C. A strict inspection procedure of base roller:Incoming inspection including surface roughness,straightness, dynamic balance,cylindricity and so on.

2. Chrome oxide ceramic layer

A. Using the famous plasma spraying machine from Switzerland supplier.

B. The evenness of 80% ceramic powder can be controlled between 15u-35u

C. The hardness of chrome oxide ceramics can reach 1200HV.

3. Antiseptic treatment

we use the nanoscopic sealant to coat on the surface of the ceramic which can reach the tiny cell to protect the base roller from solvent corrosion.

4. Precise delivery on the inks

First,we make trial engraving before the real engraving.

Second,we use the scanner to scan each layer to test the volume of the cell

Third,according to the relationship between the LPI and BCM , we can make sure whether the LPI is workable.

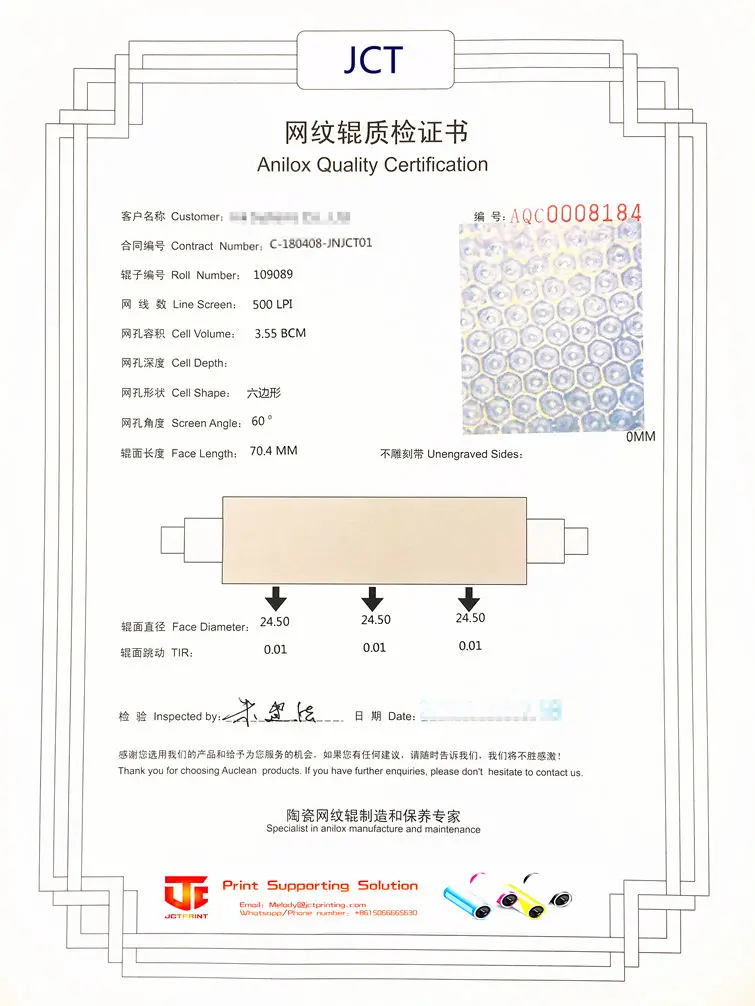

5. Quality Control

We have the quality control system during the whole production from the very beginning to the end to make sure each roller is qualified. And we will issue the certification for our customers after the products are finished.

6. Service life

Under nomal operation and maintenance,our ceramic anilox rollers can work 8-10years or even longer.

FAQ:

As the leading manufacturer of ceramic anilox roller,we have been in this field for more than 25 years,and we have plenty experience in making rollers such as ceramic anilox rollers,rubber rollers and so on.

2. Why should we choose you?

We can provide you not only the competitive price product but also most satisfactory supporting service.

3. How can we get the price?

A.The drawing of the ceramic anilox roller if possible(or you can get a estimate price by telling us the total length,effective face length,diameter as the following picture.

B.LPI an BCM

C.Where do you use the ceramic anilox roller?flexo printing machine,coating machine or offset UV unit?

4. How long is the lead time?

Usually it will take 30 days to produce the roller,but it also depends on the quantity and customer’s requirement.