Jctprint Machinery Co., Ltd

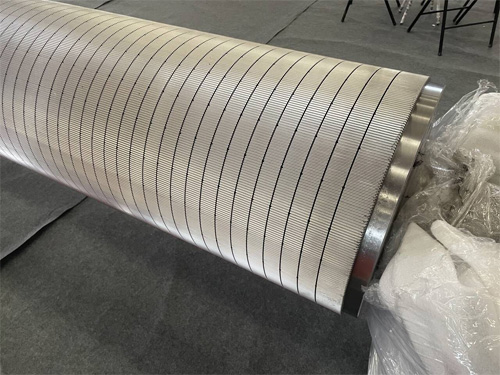

Corrugating roller

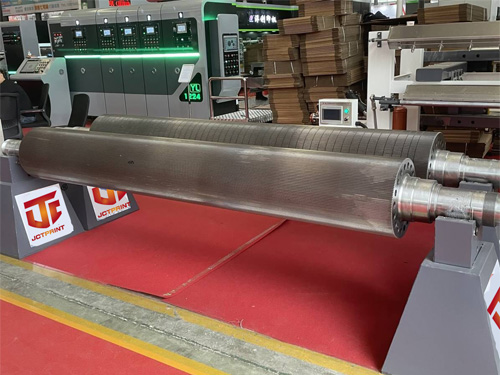

Corrugating roller is the most important part of corrugated cardboard production equipment, it is called the heart of high-speed corrugated cardboard production line.

JCTPRINT firmly believes that strictly controlling each production process can bring customers the best quality corrugated rollers.

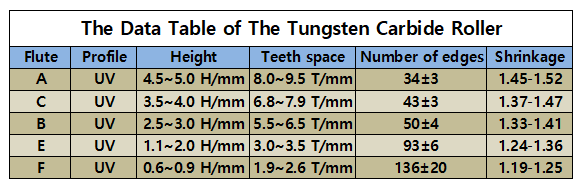

Custom parameters

Various materials are available

Chrome plating, tungsten carbide, alloy steel

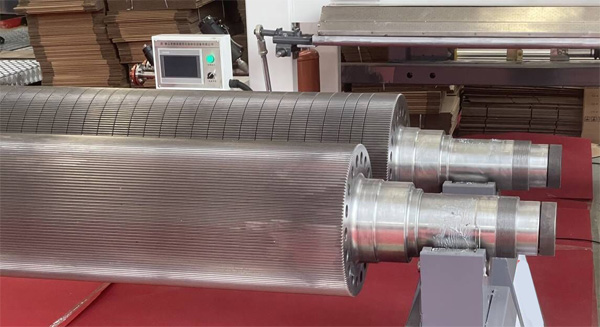

JCTPRINT Factory

Professional customer service quick reply

JCTPRINT Is the Supplier of Choice

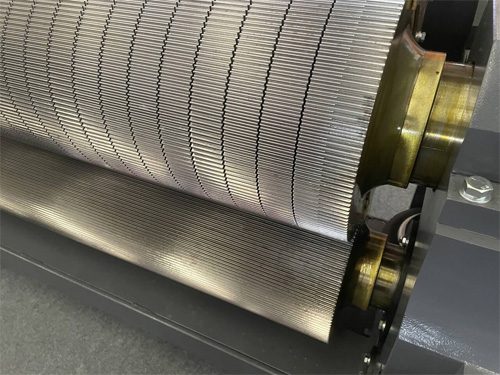

Selection of raw materials

Dedicated special 50CrMo alloy steel forgings, high-quality tungsten carbide and chromium coating are selected to make the surface hardness of corrugated rolls > hv1250-1400.

Tight precision grinding

Each set of corrugating rollers needs to be individually designed according to parameters such as width, diameter, flute height, corrugated paper GSM, speed, etc., and it is finely ground with a high-precision automatic CNC grinder to ensure that the runout accuracy of the tooth tip circle is ≤0.02mm to achieve the best production performance.

Super long service life

Quality control, and strict requirements for each process make JCTPRINT's corrugating rolls have a longer service life. The service life of chrome-plated corrugated rollers is 6-8 million meters, and the service life of tungsten carbide corrugated rollers can reach 35 million meters.