Jctprint Machinery Co., Ltd

Customized Nitrile Polyurethane rubber roller for printing Steel machinery

Product overview

1.What’s rubber roller

The rubber roller is generally composed of an outer layer rubber, a hard rubber layer, a metal core, a roll neck and a vent hole.

2.Appication

Rubber roller is mainly used in papermaking, printing and dyeing, printing, grain processing, metallurgy, plastic processing and so on.

3. Classification and characteristics of rubber roller

1). Silicone roller

High temperature resistance which can reach 200-250 degrees, and good chemical resistance,but it has low tensile strength.Silicone roller can be used in fabric heat setting, plastic heat setting embossing, calendering, photocopying and so on.

2).Polyurethane rubber

It has outstanding tensile strength wear resistance and crack resistance and good resistance to a variety of solvents.

3). NBR rubber roller

NBR rubber roller can be used as printing roller, food industry rubber roller, dyeing roller in textile printing in dustry and the soft rubber roller for contacting solvent and so on.

Note: The NBR has poor ozone resistance and the operation should be avoided in a high concentration ozone environment during processing.

4). Neoprene roller

Suitable for the soft printing roller, gravure printing roller and so on.

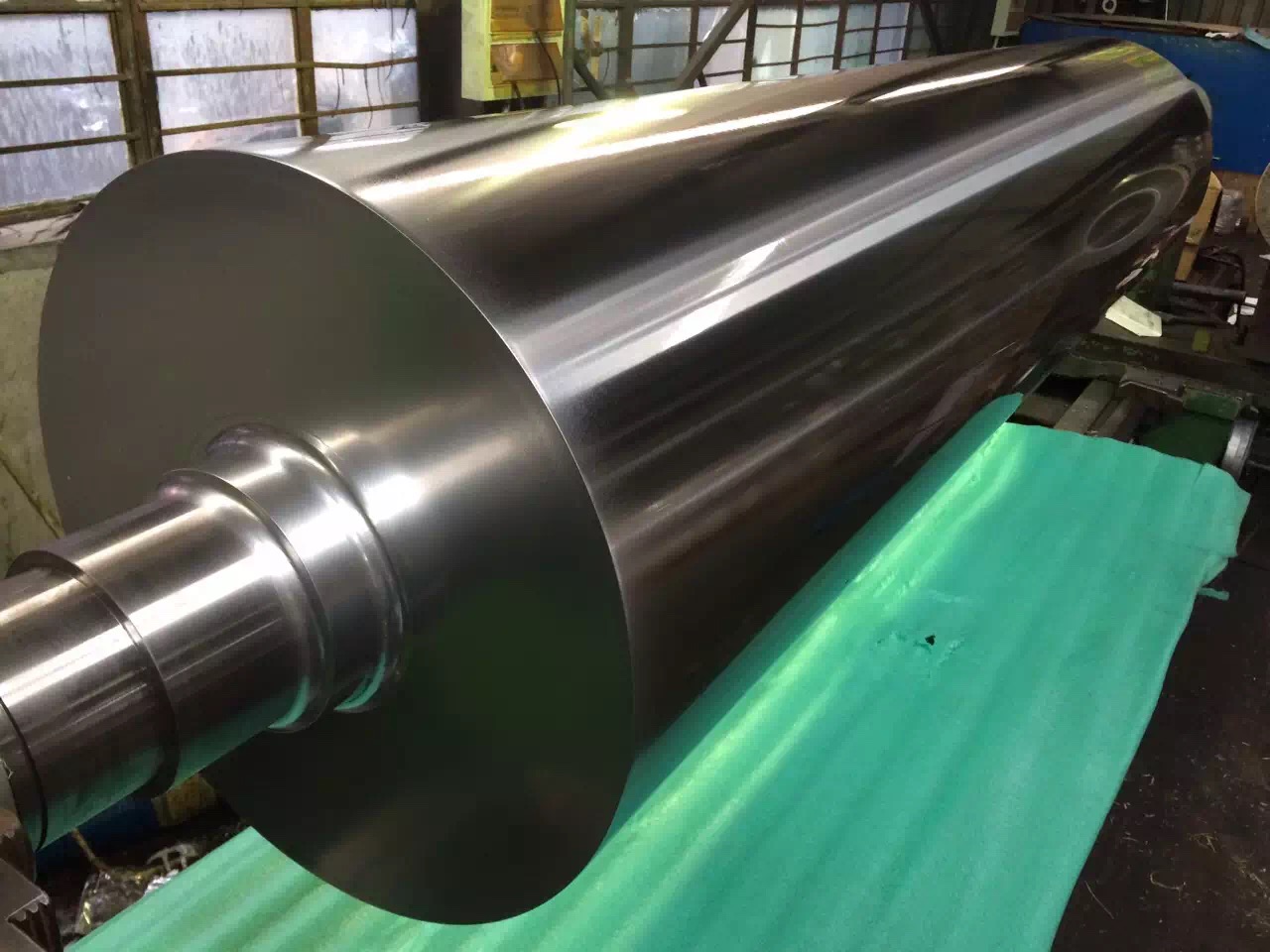

5). Mirror roller

We generally adopt 45 # steel, alloy steel seamless pipe, precision forgings as the material.The surface of the roller finish degree can reach RA0.01. Mirror processing can ensure the roller surface flatness, balance, non-roundness, coaxial degree meet the customers’requirements.

4. Advantages of our rubber roller

A.Raw materials :

1) Base roller:

we are using is #45 steel or #20steel seamless pipe.And we are adopting a reasonable thickness base roller according to customer’s drawing.

Some manufacturers will reduce the thickness of the steel pipe in order to get the price advantage.Such roller can’t meet the standards.But we won’t do that.

2)Rubber:

Our rubber are all imported from Germany or the US and then we mix them in our factory.The rubber coating technical we are using is winding technical.

We casting the rubber on the base roller layer by layer and then vulcanize it to make the green rubber into mature rubber.

While other manufacturers are using sheet coating technical,and the rubber is cold in processing and will cause adhesion problems easily.

B. Production process:

1)Dynamic balancing:Before installing shaft head, we will do dynamic balancing test twice for each rubber roller,which will ensure the using effect.

2) Hot charging technicals:Adopt hot charging technicals to install the shaft head, and then weld after contraction to ensure the quality of shaft installation.While other supplier are welding the shaft head directly.

Workshop pictures

Company information

Contact

Helen Shen

Jinan Jinchangtai Industry And Trade Co., Ltd

Add:Lushangshengjing Plaza Building B-1406, No.6 Qingfeng Road,

Jinan, Shandong, 250014, China

Tel:0086-0531-61300169

Fax:0086-0531-61300169

Mobile/wechat/Whasapp/skype:0086-18660813189

Email:[email protected]