Jctprint Machinery Co., Ltd

We can provide:

1. Assistance from first idea through prototype

2. Quick delivery of prototypes or production needs

3. Design assistance and parts consolidation

4. In-house mold design (Insert, polyurethane, urethane molding)

5. In-house formulations to provide the best possible urethane for your application

6. Low-cost tooling

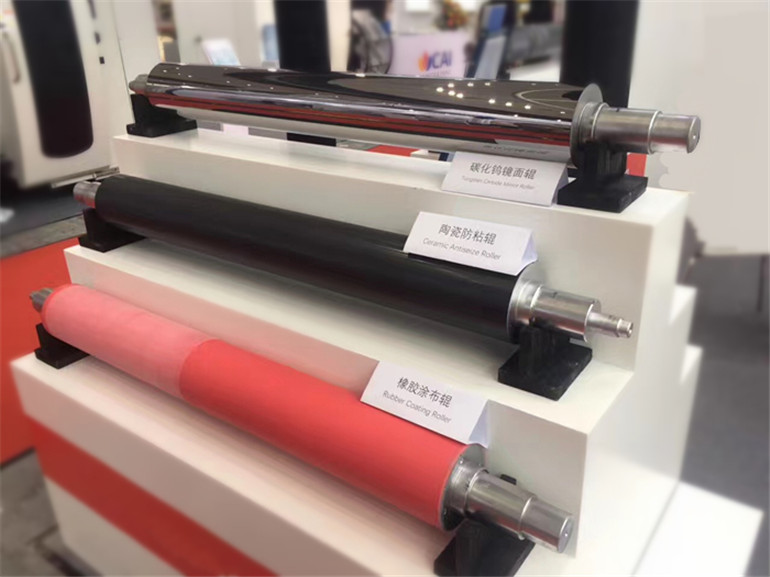

We specialized producing Silicone Rubber Rollers. Various kinds of rubber rollers and printing rollers.

If you are require of the rubber roller ,pls send me your samples and drawings by email: melody@jctprinting.com .

We can provide:

1. Assistance from first idea through prototype

2. Quick delivery of prototypes or production needs

3. Design assistance and parts consolidation

4. In-house mold design (Insert, polyurethane, urethane molding)

5. In-house formulations to provide the best possible urethane for your application

6. Low-cost tooling

|

Material |

EPDM,NR,Silicone,NBR,Rubber,or Custom Compound |

|

Size |

According to your drawings |

|

Color |

Black,white,red,green,transparent or any color according to Pantone colors |

|

Finish |

High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

|

Type |

Round,square,rectangular,or any nonstandard shape as request |

|

Logo |

Debossed,embossed,printed logo or as request |

Usage of Printing machine

Offset printing machine;

Gravure printing machine;

Flexo printing machine;

Carton production line and so on

Rubber of our rollers:

1). Raw material : NBR,Silicone,Rubber,Polyurethane,EPDM .

While other manufacturers are using sheet coating technical,and the rubber is cold in processing and will cause adhesion problems easily.

Base roller:

We are using #45 steel , #201stainless steel #304stainless steel and 5# aluminum seamless pipe as the base roller.And we are adopting a reasonable thickness base roller according to customer’s drawing.

Some manufacturers will reduce the thickness of the steel pipe in order to get the price advantage.Such roller can’t meet the standards.But we won’t do that.

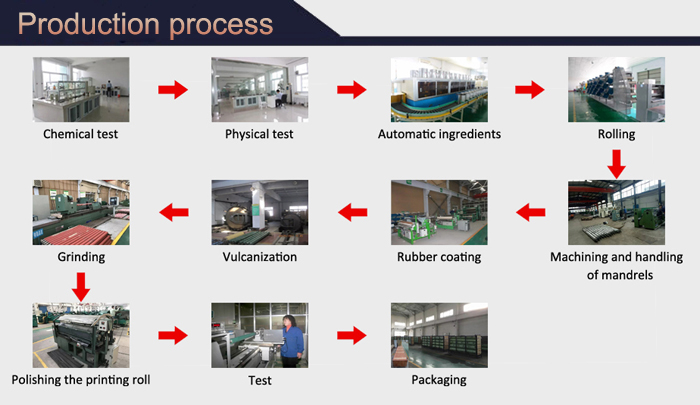

Processing of the rubber roller

The processing includes roller core blasting, bonding treatment, adhesive molding, wrapping, wire winding, vulcanization tank vulcanization and surface processing.

As an experienced printing roller manufacturer, we have perfect studying and exploiting mechanism and facilities, and supply high quality products as per customers' requirements. Our main products include rubber roller, flexo cylinder and anilox roller, etc.

We are willing to assist with design & technical difficulties; we are unrivalled at providing you with the most efficient and cost effective printing roller products without compromising on quality.

We aim to offer the most competitive prices whilst still retaining high levels of Quality and Service.

Any inquiry will be replied to within 12 hours, and any delivery of quality products will be shipped on time as agreed.

For Fast Quotation,Please Inform Below Details

Pls let me know the following informations:

Production type

Material specification (or let us know the using environmental)

Size details? (or provide drawings or samples for refference)

Quantity request

Prefer color

Contact us