Jctprint Machinery Co., Ltd

1. Application

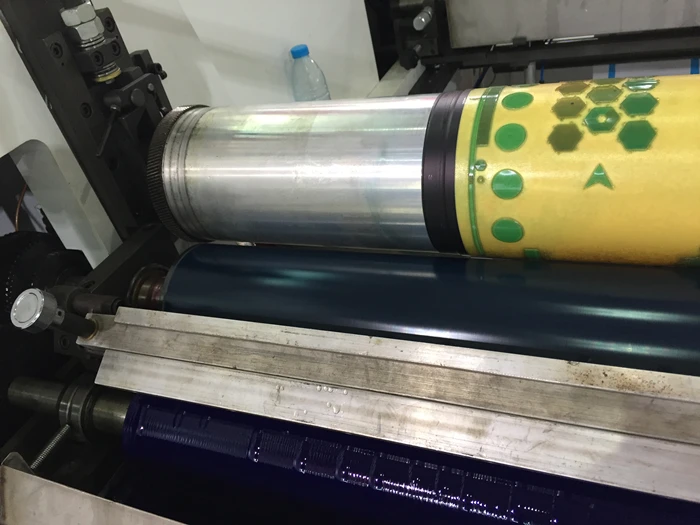

Flexo printing cylinders can be used on most of letterpress, stacked flexo machine,satellite flexo machine,unit flexo machine and combination presses.

2. Process of flexo printing cylinder

→Cylinder Initial lathe

→Initial static equilibrium

→Shaft over current assembly welding

→Fine lathe

→Fine static equilibrium and dynamtic balance

→Surface treatment: plating,fine grinding,polishing,chroming

→Packaging

3. Features

A.Circumference of Printing Cylinder: 100-1500mm

B.There are lines on the cylinder which can make sure the printing plate on right place

C.Precision on the cylinder production

| Surface Hardness | ≥HRC50,with strong corrosion resistance |

| Roughness | ≥ Ra0.16, without air hole or groove |

| Temperature difference | ≤±1°C |

| Thermal deformation | ≤0.01mm |

| Concentricity | 0-15microns |

| Straightness | ≤0.2mm |

| Cylindricity | ≤0.2mm |

4. Advantage

A. High-quality materials for base roller

We adopt 45# seamless steel tube or No5 series aluminum as the base roller,which have enough stiffness to make sure the bending deflection is not over the allowable value under heavy pressure.

B. Dynamic balance test twice

We will do dynamic balance test twice on each cylinders,the radial jumped error will be less than±0.005,which will help do evenly distribution of the inks on the printing material.

C.Advanced welding technology

Adopt CO2 protective welding orTIG welding technology at the head of the roller,will assure the welding is continuous and smooth.

D. Heating treatment process

This process will increased hardness and to prevent the cylinder from deformation and will assure the geometric accuracy and long service life.

Wecome to send inquiry to us!

Contact information:

Jennifer Song

Mob/whatsapp/skype: +8618560215003

Email: [email protected]

1. How many years have you been producing flexo printing cylinders?

As the leading manufacturer of flexo printing cylinders,we have been in this field for more than 10years,and we have plenty experience in making rollers such as flexo printing cylinders,ceramic anilox rollers,rubber rollers and so on.

2. Why choose us?

We can provide you not only the competitive price product but also most satisfactory supporting service.

3. How can we get the price?

A.The drawing of the flexo priting cylinder and the drawing of the gear if possible

B. The model and brand name of the printing machine.

C. The printing width and printing repeat

4. How long is the lead time?

Usually it will take 20days to produce the roller,but it also depends on the quantity and customer’s requirement.