Jctprint Machinery Co., Ltd

As the leading manufacturer of flexographic laser engraving ceramic anilox ,printing cylinders and other relevant products in connection with flexo, our mission is to serve flexographic printing companies in and abroad with good quality and best service.

Firstly, uniform and stable ink transfer, using the concave carrier on the surface to transfer and control the ink, thus having the functions of ink storage, ink distribution, and ink transfer;

Secondly, avoiding the ink stick, because the anilox roller has high processing precision, the ink can be well transferred even under the light pressure state, thereby reducing and avoiding the generation of the ink stick and the ghost image;

Thirdly, increasing the speed of the car, due to the use of anilox roller, effectively overcomes the phenomenon of "flying ink" and plays a vital role in increasing the speed of the printing press.

The Anilox rollers are classified according to the material they are plated or sprayed on, and are mainly chrome-plated anilox rollers and ceramic anilox rollers.

The difference between chrome anilox roller and ceramic anilox roller:

Metal anilox rolls are made by mechanical extrusion or chemical etching.

The highest production line number is 300LPI. Advantages: low cost

Disadvantages: unable to transfer ink to high-line flexo plates, easy to wear

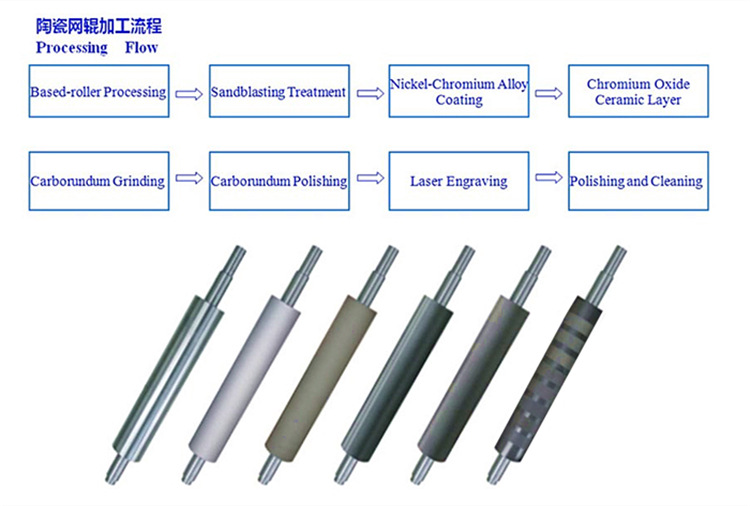

Ceramic anilox roller uses laser engraving to make mesh, the highest production line

2000LPI.

Advantages: It can be suitable for high-line printing, uniform ink transmission and wear resistance

Disadvantages: need to be cleaned frequently

LPI means line screen per inch,BCM is unit of cell volume,1BCM =1.55㎝³/m².

For example,500LPI means each 25.4mm length,the quantity of cell is 500pieces,the length is fixed.So if LPI is higher,the cells’ quantity is more ,the volume of cell is smaller,then the inking quantity is smaller.

Company information: