Jctprint Machinery Co., Ltd

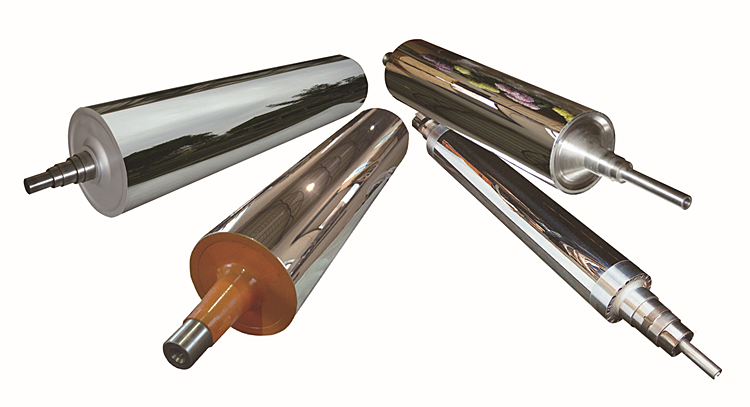

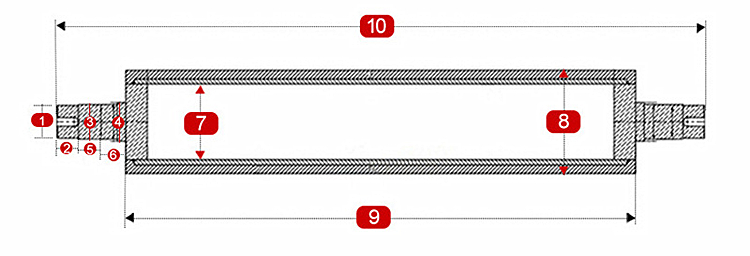

Mirror roller parameter

| cooling or heating temperature difference | ≤±1℃ |

| Surface hardness | HRC55~58 |

| Hardness after chrome plating | HRC62 |

| Thermal deformation | ≤±0.01mm |

| Roll surface roughness | Ra0.01~0.005 |

| smoothness(super mirror) | Level 14 |

Custom design

Product material: optional stainless steel, low carbon steel, high carbon steel, alloy steel, etc.

Product manufacturing range: diameter 300-800mm, length 3000mm

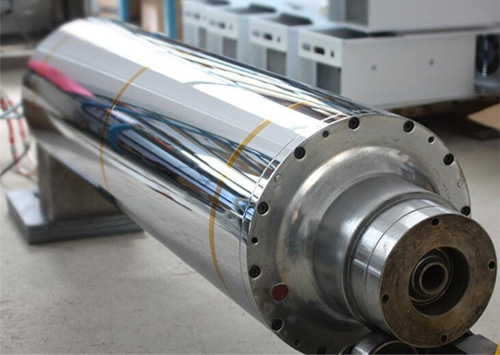

Ensure that there are no problems such as vibration, streaks, hairlines, and water ripples after mirror processing

Contact us for a quick quote and provide you with customized services

Advantages of JCTPRINT mirror roller

High hardness, especially durable

The high durability is determined by the chrome plating layer, the JCTPRINT chrome plating thickness reaches 100 microns and the hardness reaches HRC58-66.Currently only 20% of manufacturers can do it.

The production process is very mature

Roller Initial lathe→Fine lathe(Fine turning, rough grinding)→Static (dynamic) balance→Rust removal→copper platin→Chrome plating→fine grinding and polishing→Qualtiy inspection→Packaging.

Strict requirements on the production process

JCTPRINT strictly controls the concentricity of the mirror roller and the surface roughness of the mirror through precision grinding.

Application - calendering

Leather Industry : artificial leather and other kinds of leather

Plastic Industry : PVC,ABA,PP,PT,PC and other kinds of plastic

Metallurgical Industry : all kinds of non-ferrous metal

Paper Industry : various paper

Printing and Dyeing Industry : cotton, silk, chemical fiber, linen, wool and their blended fabrics

Customer on the machine real shot