Jctprint Machinery Co., Ltd

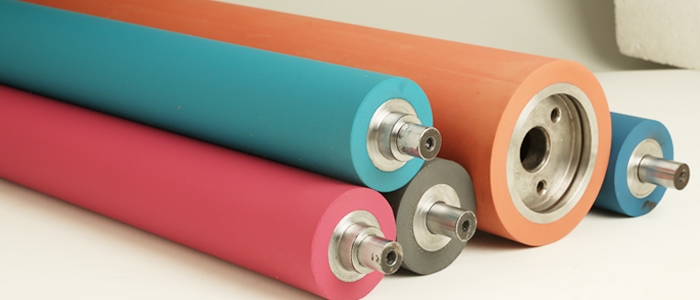

JCTPRINT printing rubber roller pursues the most perfect printing effect.

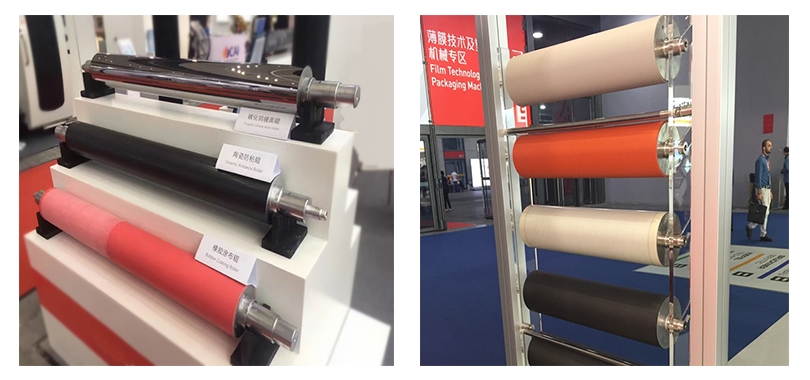

Application of printing rubber roller

*Ink rubber roller:The ink roller is mainly used to transfer ink to the printing plate to ensure that the ink is evenly coated on the printing surface.

*Printing rubber roller:Printing rollers are usually used to transfer printing pressure to transfer patterns or text from the printing plate to the printing medium.

*Coating rubber roller:Mainly used for coating ink, paint or other special coatings on printing media. Coating rollers distribute coating evenly and control its thickness and quality.

*Lamination rubber roller:Laminating rolls use adhesives and high heat to coat the surface with a protective layer.

*Hot stamping rubber roller:Hot stamping rolls apply foil or pre-printed heat transfers by providing heat and contact pressure.

There are also metering rollers, ink transfer rollers, ink fountain rollers, ink form rollers, nip rollers, etc.

Choose our advantage.

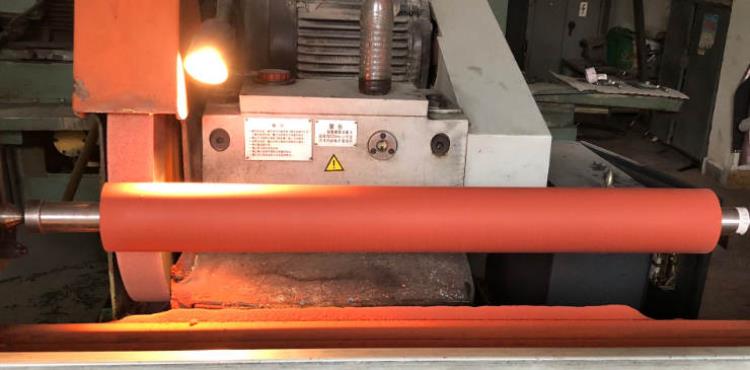

*Base Roll:We use #45 steel, #201 stainless steel, #304 stainless steel and 5# aluminum seamless pipe as the base roll. And according to the requirements of the customer's drawing, the bottom roller with a reasonable thickness is used.

*Rubber:Take imported rubber from Germany or the US and mix them together. Using winding technology, the raw rubber is poured on the base material layer by layer, and vulcanized into cooked rubber.

*Dynamic balancing:Before installing the shaft head, two dynamic balance tests will be performed on each rubber roller to ensure the use effect.

*Hot charging technicals: Adopt hot charging technicals to install the shaft head, and then weld after contraction to ensure the quality of shaft installation.

What makes JCTPRINT special?

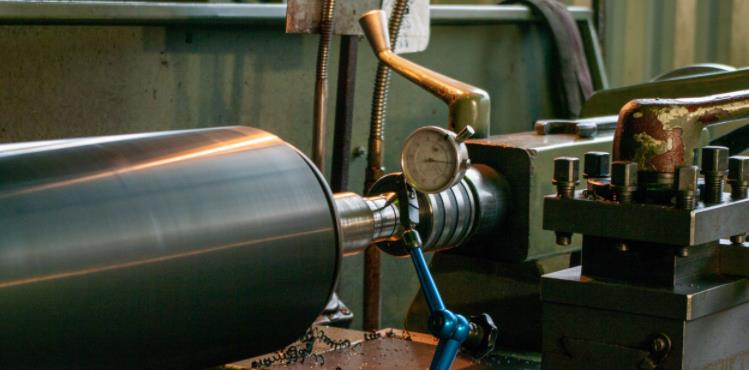

♦The roller is made by an automatic device, and the concentricity is 100% tested.

♦Imported laser detector is used to ensure that the geometric size and accuracy of the roller can reach 0.01mm.

♦Rollers and supporting parts are manufactured in accordance with ISO/BS/DIN/CEMA and other standards.

What can JCTPRINT do for you?

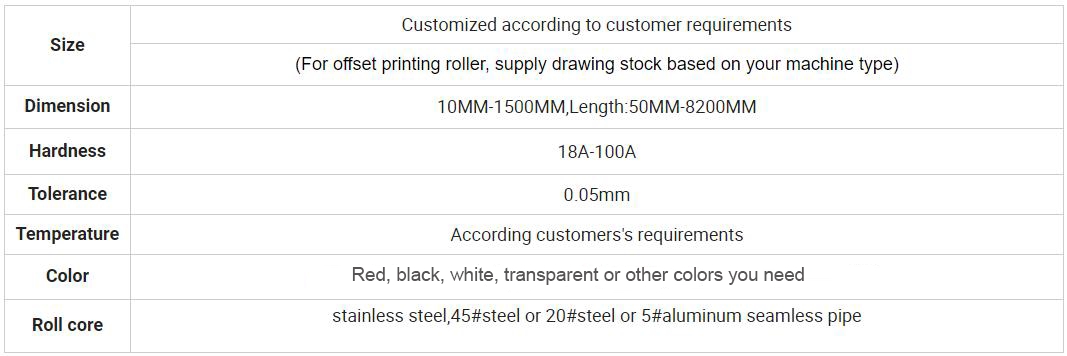

♦Professional customization

Rubber rollers are used in different industries and purposes. JCTPRINT is an expert in customized solutions. We have a deep understanding of different types of rubber rollers and can provide you with all-round help.

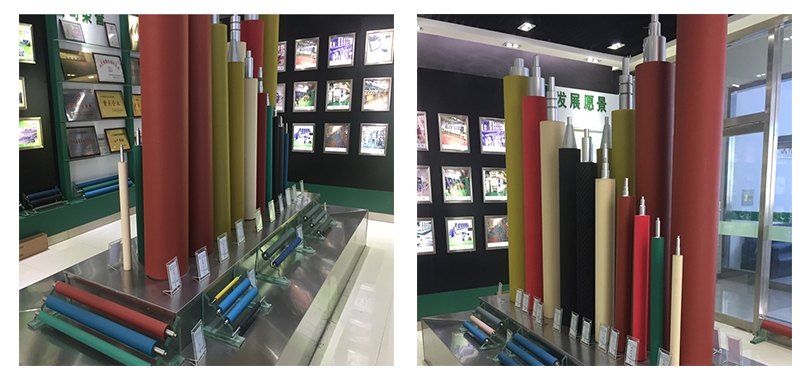

♦Sizes, Finishes and Shapes

We have different finishes and shapes to make according to your needs, sizes from 5mm to 8m for your choice.

♦Fast delivery

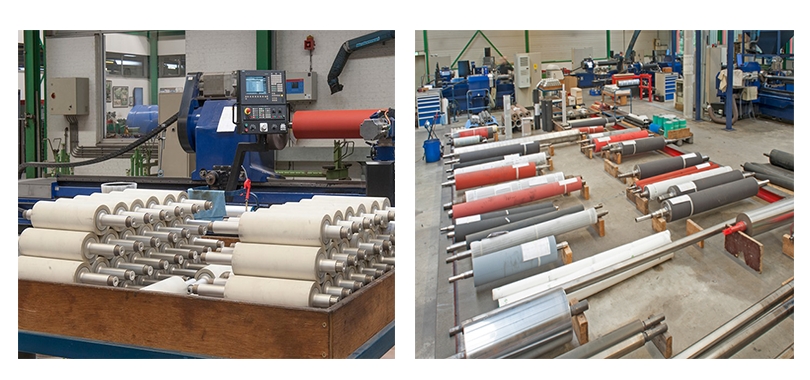

JCTPRINT has 3 automated production lines to ensure delivery within 15-25 days.

Factory List

Exhibition

We will be happy to create the ideal roller for your application.