Jctprint Machinery Co., Ltd

Widely used in industrial commerce, printing, food and medical fields. JCTPRINT will design the most suitable rubber roller for you according to your needs.

Any industry, we can provide the most suitable rubber roller

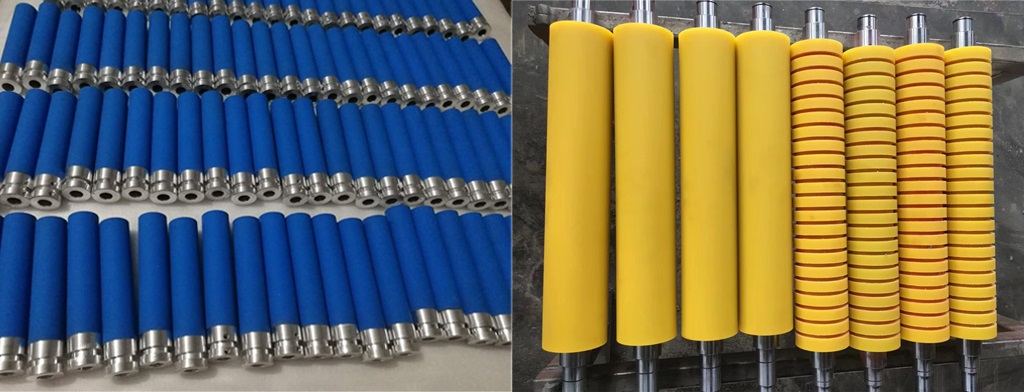

Learn about the rubber rollers we are producing.

Natural rubber roller

Excellent elasticity and mechanical strength, good alkali resistance, used for compression rubber rollers in textile, papermaking leather, packaging and other equipment and traction rubber rollers in metallurgy, mining and other industries.

NBR butyronitrile rubber roller

Good oil resistance, good chemical stability, good processing performance, good wear resistance, good heat resistance, strong adhesion.

silicone rubber roller

Food grade, with excellent high and low temperature resistance, aging resistance, excellent dielectric properties, physiological inertia.

polyurethane rubber roller

Wear-resistant, low cost. Features, soluble in water, good mechanical properties.

EPDM rubber roller

Solvent resistance, aging resistance.Resistant to strong acids and alkalis, it is often used in gravure printing machines

Neoprene rubber roller

Excellent wear resistance, high fire resistance, aging resistance, good heat resistance, oil resistance and acid and alkali resistance.

Hypalon rubber roller

Acid and alkali resistance, high temperature resistance.

carbon fiber roller

Light weight, high strength, high temperature resistance. Applied to special industries such as wide width film.

Customer customization

For your actual application scenarios, select raw materials, blending ratios, production processes, and special inspections.

JCTPRINT rubber roller will be your best choice!

JCTPRINT provides you with customized solutions to ensure your production process is stable and efficient. JCTPRINT's rubber rollers are high-quality and reliable, let the rubber rollers help you succeed.

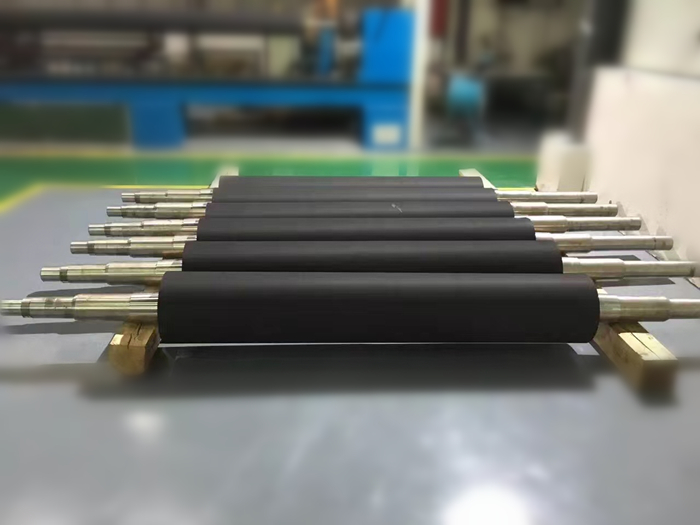

Each department of rubber produces independently and has large-scale production equipment. Design, production, testing, and provide a full-process solution for each type of rubber.

Whether it is the rubber attached to the outside or the iron core inside, we use the best materials. We prepare special formulas for rubber mixing according to different application scenarios of customers.

Two rubber wrapping and three dynamic balance inspections ensure the best beating flatness of the rubber roller. The shaft head is heat-fitted and reinforced twice. Allows you to achieve the level of precision of JCTPRINT in the production process.

No matter what your needs are, JCTPRINT will do our best to meet them.

Here is a performance comparison of some commonly used materials

Rubber Roller Factory

Exhibition list

JCTPRINT's rubber rollers have been widely praised and have many repeat customers.

Escort your rubber rollers with the safest packaging

To make sure your products reach your hands safely, use imitation UV paper (black inside) to prevent rubber from aging.

JCTPRINT rubber roller will bring you the greatest production efficiency, come and discuss your business!