Jctprint Machinery Co., Ltd

Types of Anilox Rolls

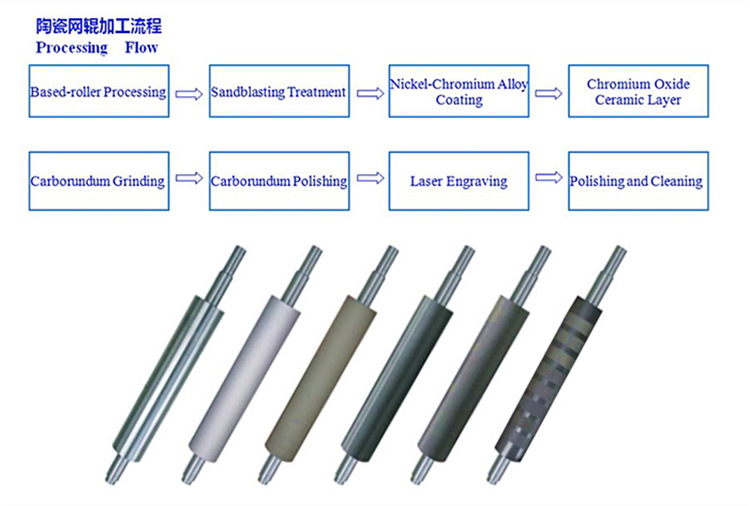

Common anilox rolls include metal anilox rolls and ceramic anilox rolls.

In terms of style, it is divided into belt shaft type and anilox roller sleeve type (GTT)

The ink transfer efficiency, printing accuracy and service life of ceramic anilox rollers are much higher than traditional metal anilox rollers.

The anilox roller is used to quantitatively and uniformly transmit the required ink to the graphic part of the printing plate.

It is a key component of the ink transfer system of the flexo printing equipment. Its manufacturing accuracy directly affects the quality of the flexo printing.

Today, through the introduction and upgrading of technology and the use of anilox roller ceramic spray coating electronic engraving machine, the processing and manufacturing accuracy of anilox roller has been significantly improved, and the service life has also been increased several times, and the maximum number of lines can reach 2000 lines/inch.

New Application of Anilox Roller

Anilox rollers are also widely used in new energy and lithium battery coating and printing industries, from which more production lines of our company are derived: Lithium battery coating roller, Battery coating roller, New energy coating roller, micro gravure roll, Positive and negative electrode separator coating roller, Battery Separator Coating Roller, PP Diaphragm Coating Roller, PVDF film coating roll, Alumina Dioxide Coating Roller, Slurry coating roll, etc.

How to choose the anilox roller

Founded in 1980, JCTPRINT is a large multinational company specializing in the production of flexo printing equipment, anilox rollers, rubber rollers and magnetic rollers.

It has a series of high-end processing equipment made in Germany, Japan, Switzerland, etc.

At the same time, the company also produces printing rollers such as inflatable shafts, aluminum guide rollers, etc., forming an operating system that integrates R&D, production, sales and service.

JCTPRINT flexo plate cylinder production line

As a well-known anilox roller manufacturer in China, our advantages

1.Has more than a dozen imported ALE laser engraving machines with strong processing power

2.The most suitable opening ratio for engraving ensures the accuracy of ink transfer and reduces the cost of ink consumption

3.Ceramic spray (Cr2O3 for durability and wear resistance) can reach 1200HV hardness

4.The ceramic surface of the nanoscale encapsulant has good corrosion resistance

5.Scan each layer with a scanner to test the volume of the cells and then determine the LPI we want to achieve based on the relationship between LPI and BCM

6. We have a multilingual team to answer your query

7.The delivery speed far exceeds the delivery speed of peers, we will complete the order within 15-25 days.

Mesh selection:

24 hours online, Get a quote:↓↓↓