Jctprint Machinery Co., Ltd

Custom Heidelberg Mark Andy Printing Press Anilox Roller

Features

1. Anti-wear, anti-corrosion, thermal stability, long-life service and high cost.

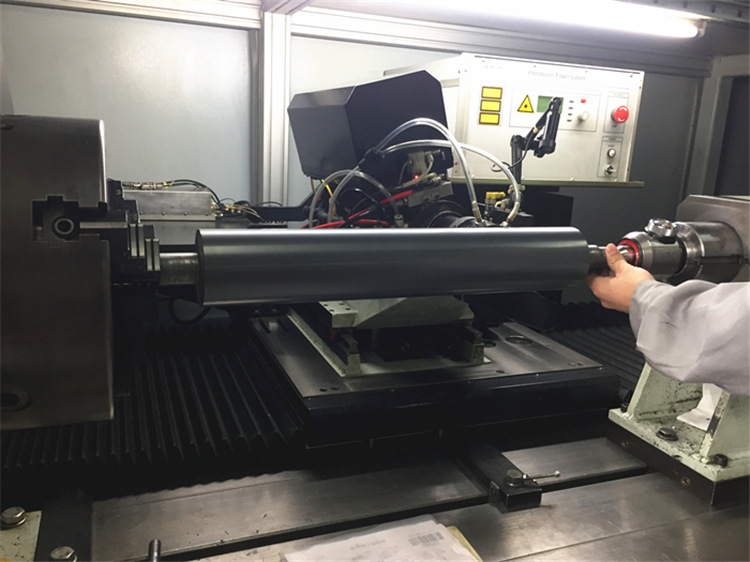

2. The unit engraved by the ALE fiber laser engraving machine contains a large amount of ink.

The cells have a regular shape and a smooth cell wall and cell bottom. Therefore, not only the ink in the cells can be quickly released, but also the cleaning can be easily performed.

3. The strict process of plasma spraying ceramic layer ensures the porosity, thickness and uniformity of the layer.

4. Combine the super-alloy stainless steel layer to ensure that the ceramic layer is firmly bonded to the drum base. Therefore, it can effectively insert corrosive substances of printing ink into the bottom of the roller.

Application:

Flexographic printing, lithography, gravure printing

2, flexible packaging

3. Labels, envelopes, paper forms, handbags

Corrugated box

Plastic film, coated paper products, glazing

6. Wallpapers, wood grain paper, etc.

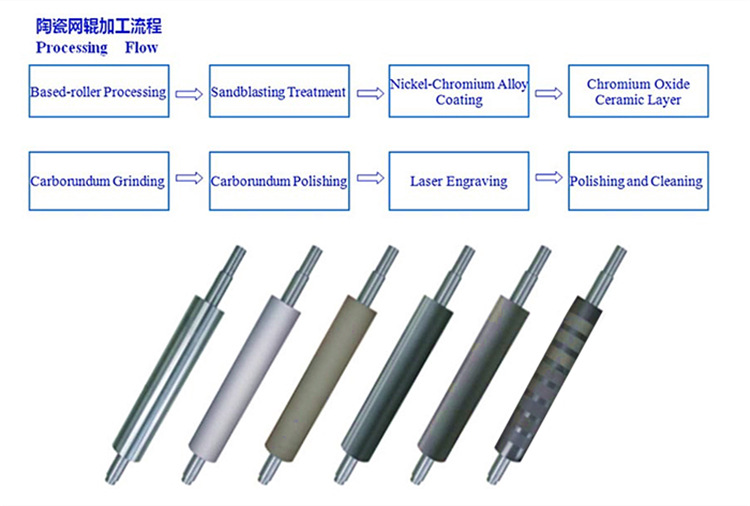

The Manufacturing processes as follows:

Roller Specification:

Roller Diameter: φ25~600mm

Surface Length: L100~5800mm

Screen Line: 50~2000 L/in ( 20~800 L/cm )

Cell Specification:

Cell Shape: Diamond ,Hexagon,Tri-helical and other special shapes

Cell Angle: 60°,45°,30°and other special requirements,Tri-heliacal 1~89°

Advantages:

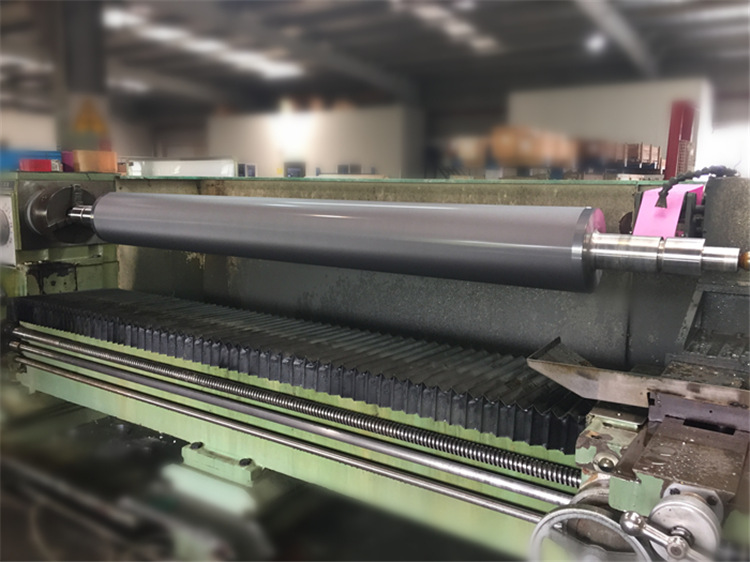

1. Adopt a strict ceramic layer plasma spraying process to ensure the porosity, thickness and uniformity of the ceramic layer.

2. Multi-beam laser engraving, mesh rule, smooth mesh wall, flat net bottom, large ink transfer, fast ink release, easy to clean.

3. All products are provided with a grid capacity test report to ensure the accuracy of the ink load.

4. Sleeve type lightweight ceramic anilox roller, can be customized according to user requirements.

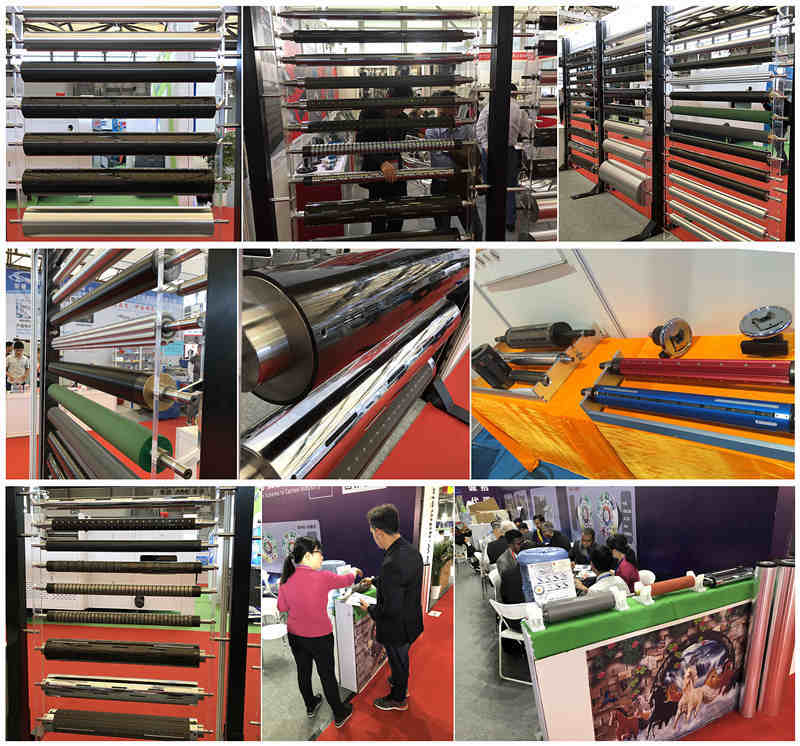

Photos of ceramic anilox roller:

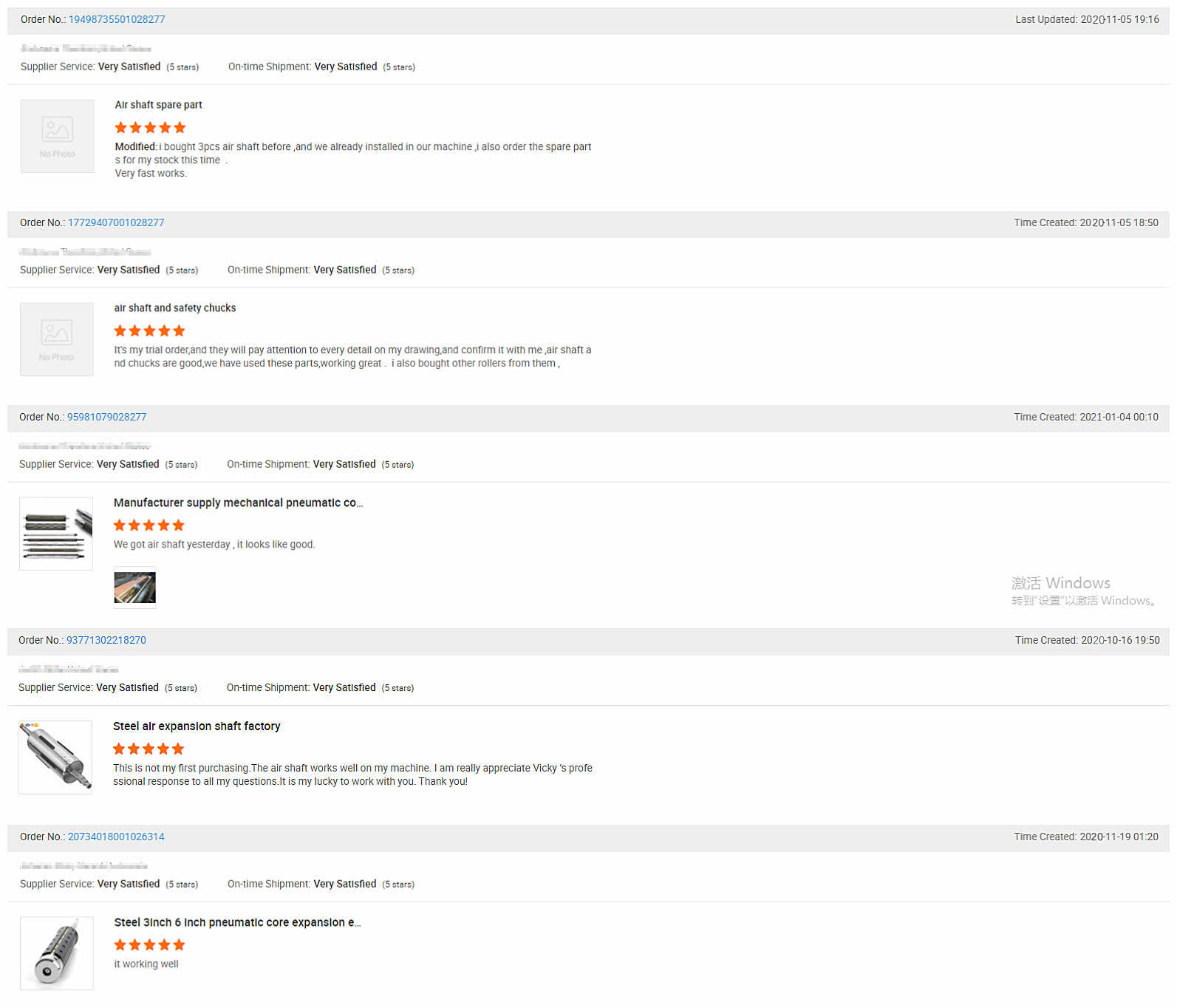

Customer Reviews

FAQ:

1.Why choose us, JCTPRINT ceramic anilox Roller?

Focus on roller all the time.

Advanced technology.

Excellent staff

Know your demands very well.

2. What's the surface coating of roller?

Chroming, Ceramic, ect.

3. What do you provide before making roller?

Drawing.

Quantity.

Pattern or samples.(if possible)