Jctprint Machinery Co., Ltd

The anilox roller will be further applied in post-finishing finishing such as coating, glazing and the like. At present, most of the anilox rolls for coating and glazing use chrome-plated metal anilox rolls, and even ceramic anilox rolls are used for medium and low net counts.

With the advancement of society and the continuous improvement of the quality requirements of printed products, the thickness of the coating will be developed in the direction of thinning and homogenization, in order to save materials, improve gloss and visual effects. Therefore, a high number of ceramic anilox rolls will be further applied in this field.

High precision and high line number will be the development trend of ceramic wire roller. The modern printing industry is developing in a high quality direction. The high quality of printed products mainly includes two aspects, one is multi-color, and the other is the faithful reproducibility of layers and tones.

It will be used in the lithographic offset short ink system. Lithographic offset printing is still the main printing method for competing with flexo printing in the market. Therefore, if a short ink path system, that is, an anilox roller ink transfer system, can be used in lithographic offset printing, the market for ceramic anilox rolls will undergo fundamental changes, and the quality of lithographic offset printing products will be greatly improved.

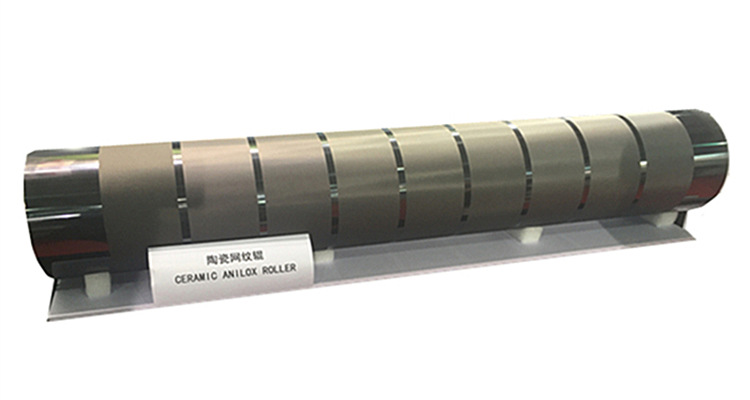

Plasma Spraying Ceramic Anilox Roller for Flexo Printing Machine

Product Description

LPI range : 80-2000 LPI

Maximum width : 4000mm 5250mm ( with axis)

Diameter range :25-600 mm

Screen angle : 1-89 degree

Cell shape : hexagon , quadrangle and line , etc and the many morn cell shapes may meet your requirement .

Ceramic Anilox Roller Or Steel Anilox Roller .

Application :Main used in printing, coating, laminating, glazing etc.

Advantage :Wear resistance; Corrosion resistance; High-temperature resistance; With stable and wide regulating range of ink transfer; Easy to clean; Long life time to use.

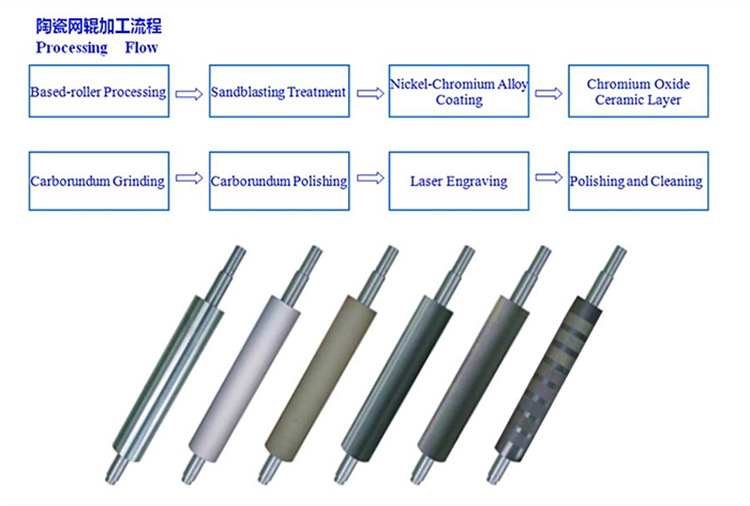

Processing Flow

Now let us introduce our main production process and the reasons for you to choose us :

Based-roller Processing → Sandblasting Treatment → Nickel-chromium Alloy Coating →Chromium Oxide Ceramic Layer → Carborundum Grinding → Carborundum Polishing→Laser Engraving → Polishing and Cleaning .

* Laser engraving equipment

Using the world's most advanced ALE fiber-optic laser engraving equipment, dot shape deeper and more smooth than ordinary laser engraving, is conducive to ink transfer uniformity and has a large quantity of ink-containing . .

* The plasma spraying equipment

Swiss SULZER Sulzer Metco Triplex spraying systems, high coating quality, low porosity, micro-hardness can reach 1300HV-1450HV, after coating with precision grinding machine, to better ensure the accuracy Roller.

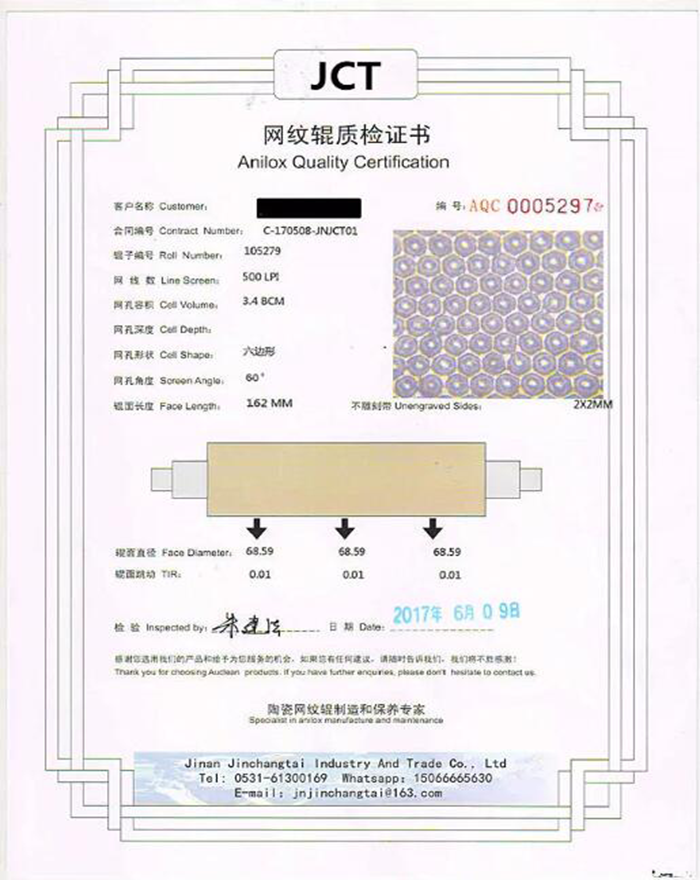

* Tester

British imports using advanced tester, designed for ceramic spinning rollers designed a network tester, can accurately measure the volume of cell shape (dot size, open area and depth, etc.)

* Service life

Under nomal operation and maintenance,our ceramic anilox rollers can work 8-10years or even longer.

Company Information

Packaging

We have two types of packaging wooden box and strong carton.

Contact us

For more information of our product, please check our website :http://jinchangtai.

Or get in touch with us directly to :

Ms. Vicky (EXP. MANAGER)